|

|

#1 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

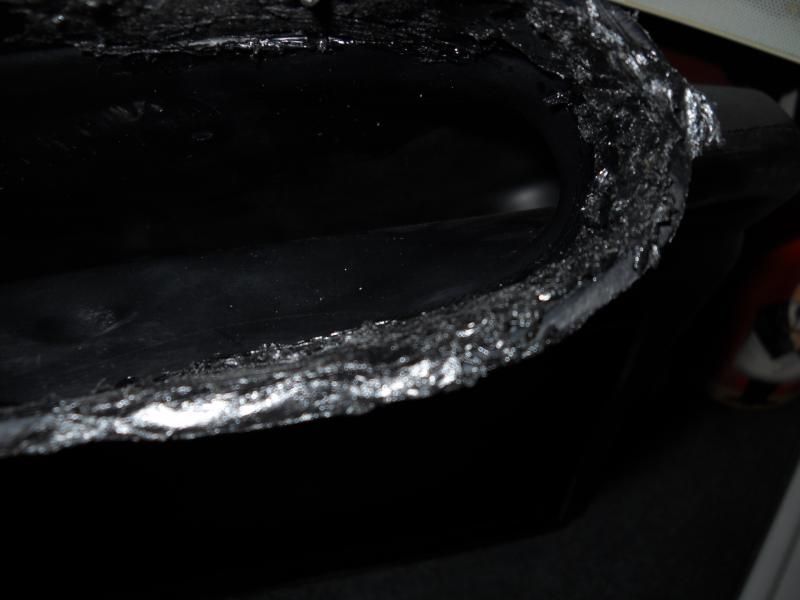

Bought this from a form member its an AO engineering intake, the neck was really bust up on it and filled with JB weld which was falling out. I bought a $16 Plastic Welder from Menards...the one that looks like a soldering iron, and used that and my heat gun to melt the welding rods...

Right now it looks rough, but this is without much prep, needs some more attention, but it seems to have bonded well and it is functional. I will go back and add in some in a few areas and then hand sand it smooth. Areas were there is a gap I backed with aluminum tape and bridged it across Before; JB Weld removed and plastic angled  Welded up  Minor Clean up

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

#2 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

#3 |

Join Date: Nov 2013

Location: Jacksonville, NC

Posts: 48

|

Looks like that should turn out great

|

|

|

|

|

|

#4 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

Looking at some OE intakes the material is polyethylene plastic; so you would probably want HDPE welding rod or strips

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

#5 |

Join Date: Jan 2009

Location: Portland Oregon metro area (Washington side)

Posts: 3,207

|

what temp does the welding iron run at?

Do you have a way to measure it? I'm curios because I need to repair a small crack in mine. It's been there for at least 17yrs and I want to repair it. I have a temperature controlled soldering iron that I can dial up what ever temp I want. Hoping to use it. Where do you get the plastic welding rods? Is there a chance a piece could break off and get sucked into the valves? What I mean is, is the bond as strong as the original plastic? If it were to be flexed to the breaking point would it break at the bond location or somewhere else first?

__________________

Scott Vett owner since 1979._It's about the car and the people |

|

|

|

|

|

#6 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

The welder runs at 525 degrees and has a flat face on it....if prepped correctly and using a good rod, no the stuff will not come off. I would get the HDPE stuff, probably from granger or a body shop supply store. I saw a bumper repair demo and after it was repaired, we tried to rip it, could not do it.

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

#7 |

|

Join Date: Oct 2004

Posts: 1,890

|

The back-side of the AC housing will have the material composition molded in it. I would think you should expect HPDE and use the appropriate rod. Were all housings HPDE? I'd look first but I would think so. So long as the correct/compatible rod is used you should expect a good repair.

|

|

|

|

|

|

#8 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

|