|

|

#21 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

Okay here are the newest updates. I changed my oil pressure switch which was leaking like a pig and checked my oil temperature sensor. The sensor tested out fine. The problem was still there though with the advice of my good friend Mark Horner I checked the fuel pressure. I didn't think that was the problem because I changed the pumps less than a year ago. When I check the pressure at the rail it was 10 pounds and it wouldn't hold when I took power off the red test wire. So I changed the filter and while I had it off I tested fuel pressure on the filter inlet and it was still 10 pounds. Here's the kicker with the jumper wire attached to the red test wire you can clearly hear both pumps running with your ear on the tank filler. So this leads me to believe there is a faults in the rubber connector hose from the fuel pumps to the fuel line. What do you guys think??? I am going to attack it in the morning the mosquito's are out in force this evening.

|

|

|

|

|

|

#22 |

|

Join Date: Dec 2012

Location: NC

Posts: 1,783

|

I'm probably the last one to offer direction, but maybe pull the 2' pump fuse, and do complete FP tests on primary pump first.

I think that with the 2' pump on, you have the 2' pump check valve involved, which might effect accurate leakdown test for #1 pump... Could be wrong tho' |

|

|

|

|

|

#23 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

First off thank you. You wouldnt have a procedure to reference to by any chance. I was going to check voltage at the pumps tomorrow before I pulled them via the plug connector. Thanks very much

Dave. |

|

|

|

|

|

#24 |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

So far, so good: narrowed focus on fuel delivery = one if not THEE issue -

What we know: Two identical pumps, each with a check valve are "Y'ed" together in a single feed line and will provide about 52 psi (static test conditions). The problem came on suddenly. (This suggests something failing catastrophically - generally easier to find than something intermittent or insidious; a good thing, far as troubleshooting goes) Jumping the battery to the fuel pump connector (ignition switch OFF) at least ONE pump can be heard. (Both might be running, but we don't know that. However, even with ONE pump continuously running, the pressure should be 50+, NOT 10. So, for now, we can set that aside move on. We can make a mental note to verify both pumps are running at a later time, if that becomes necessary.) FP measured LOW at filter input. Analysis so far: Pressure is 10# at the filter input too. (This doesn't verify the filter isn't partially blocked, but is important to note perhaps for later, should it be necessary to test it) Also, since there is no fuel flow in the line between the pressure gauge and the pumps, there will be no pressure drop in the line, even if there was a significant blockage. So... Again, another mental note: we haven't eliminated the possibility of a restriction in the line. However, we're tracking a pressure loss (not related to flow at this time). Time to go to the pump end and see what is going on. Continuing troubleshooting... Inspect the external connections at the pump for fuel leaks. I would like to have known what the (test mode) current draw is with the test connector connected to the battery before we got to this point. But, no harm done if we do that now. Current draw in test mode in the 8-10A range would all but eliminate an electrical connection or grounding problem (but not totally eliminate the possibility...yes, another mental note to come back to, if necessary).    Pulling the pumps now will facilitate a COMPREHENSIVE visual inspection of the fuel pump assembly for anything mechanically impeding fuel delivery, e.g., a leaking hose or connection, or filter inlet blockage, etc (I actually found one of those red shop rags floating in my tank - apparently left and forgotten on a previous venture!) Each pump has an internal check valve. If either valve is bad, that could be the problem. I found that even with mouth pressure* on the fuel outlet port, I was able to discover a bad check valve. (Note: I replaced my pumps a while back and one had a bad check valve right out of the box.) *A more scientific and accurate check valve test method can be accomplished by setting the pressure regulator on an air compressor to 50# and rigging up a hose and some clamps to pressurize the pumps' outlet to verify the check valve is working. If one is leaking, then isolate each pump and test. I would suspect if you get this far, you'll have found the problem. But, IF NOT, then reinstalling the pumps and rigging up a jig to test fuel pressure at the pumps outlet feeding the fuel line is in order. And, if pressure is good there (you can even do a leak-down test too), then we can assume trouble between the inlet to the fuel line at the pump end and the fuel filter. Let's see whatcha come up with to this point, and get back to us... BE VERY CAREFUL WHEN EXPOSING THE OPEN FUEL TANK!!! No flames, good ventilation, NO ELECTRICAL SWITCHES TURNED ON OR OFF, INCLUDING THE AUTOMATIC AIR COMPRESSOR SWITCH, OR ROOM THERMOSTAT SWITCH... Good luck. Let us know... Last edited by Paul Workman; 12-03-2013 at 09:22 AM. |

|

|

|

|

|

#25 | |

|

Join Date: Dec 2012

Location: NC

Posts: 1,783

|

Quote:

Either write it down, or post result on the boards as you go, or both. ESPECIALLY as you progress in the diags testing... I got so many scratch notes written down from board feedback, calls to Jerry, Marc, Dominic, Jon / FICinj's, etc., ... |

|

|

|

|

|

|

#26 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

Paul and Schrade you guys are the best thanks guys

Dave |

|

|

|

|

|

#27 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

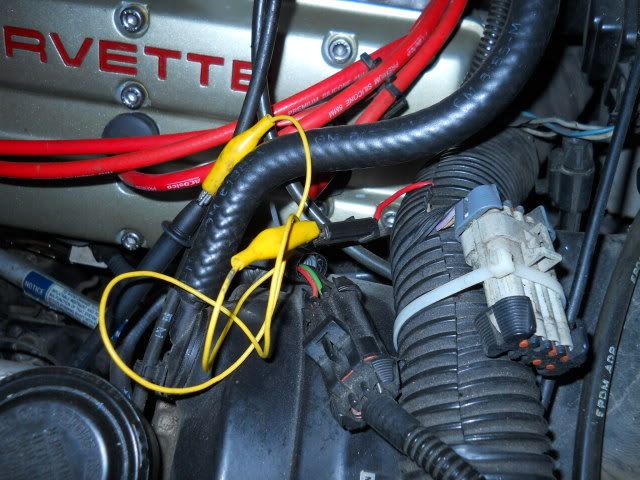

I FOUND THE PROBLEM!!!!!! One of the hoses poped off of my pumps because of those pesky plastic clamps so I removed all of them and put metal ones. I put my camera down the filler and sure enough you could see the fuel pouring out.

Dave |

|

|

|

|

|

#28 |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

Yeah... I'd call that a catastrophic (fuel delivery) failure!

One of those plastic clamps broke on mine too, when I was replacing a bad fuel pump. Went to the steel worm type clamps. No more issues so far. Glad you found it! Congratz!  Now would be a good time to see what the static and dynamic pressure is, for future reference. Just a thought.  P. |

|

|

|

|

|

#29 |

|

Join Date: Dec 2012

Location: NC

Posts: 1,783

|

Great!

Now get in, come East, and help me bolt mine up here. Pizza and a few ales around 6. EASTERN. |

|

|

|

|

|

#30 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

Now this is interesting guys. Since I put the metal clamps on the fuel pump lines The car runs better than it ever has. It runs better than when I picked it up from hammer in Idaho in 2009. It runs better than when I put the pumps in a year ago. And even runs better than when I replaced all the injectors six months ago. It has never run this good. Also I used to have a little bit of a hunting issue when I was coasting from about 30 miles an hour to 0 in neutral. That is gone now. Also my car has a Fidenza aluminum flywheel and there has always been a little chatter at Idle. You have to strain now to try to hear any sign of that. I am really amazed with the difference.

Dave |

|

|

|

|

|

|