|

|

#21 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,180

|

The Pistons have damage from a screw...apparently the culprit was never found, but he either had partners or possibly bounced around from cylinder to cylinder:

There is however no damage to liners. LGAFF 92 ZR1 #234 Last edited by LGAFF; 03-02-2018 at 07:46 AM. |

|

|

|

|

|

#22 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,180

|

The only known other issue is the cross threaded bolt for the IH:

LGAFF 91 ZR1 #234 |

|

|

|

|

|

#23 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,180

|

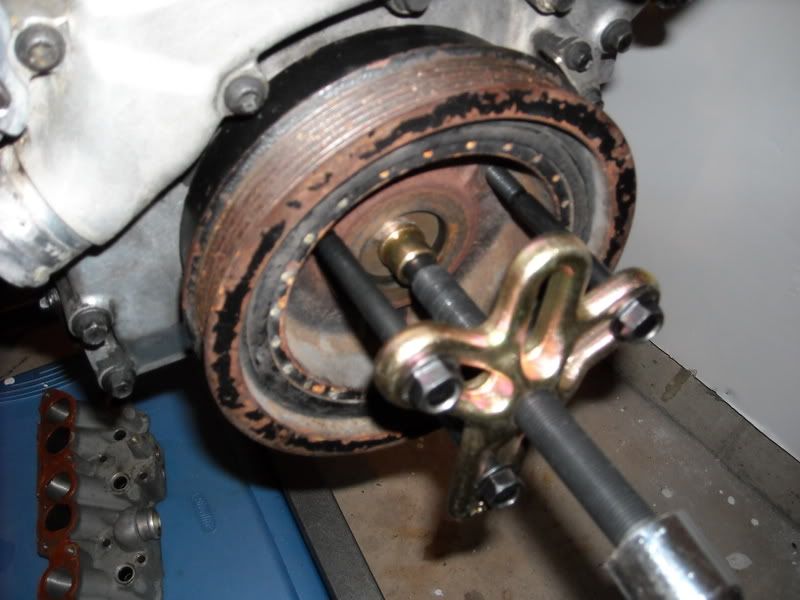

Step one in inspecting the block, etc was the removal of the balancer.

In order to hold the crank still, I placed a large head screwdriver in the crank position sensor hole, the crank has several notches in it, used for holding the crank still during cam timing. There is actually a tool that is inserted here that snaps into the notch and holds the crank still, but more to come on that. After locking the crank I removed the crank/balancer bolt. Crank position sensor hole:  Then removed the balancer:   LGAFF Last edited by LGAFF; 10-19-2008 at 08:24 PM. |

|

|

|

|

|

#24 |

|

Join Date: Oct 2005

Location: Candy Apple...yUmMy

Posts: 1,137

|

I re-used my bolts from my 368 for the 415 build and all is fine.......just turned them a few extra degrees with the wheel on the end of the torque wrench. I also re-used my head bolts on my old Z when I did the ported lpe heads from nj.

|

|

|

|

|

|

#25 |

Join Date: Jul 2007

Location: Bartlett, IL

Posts: 7,157

|

Yeah but LGAFF has NO Head Bolts.. that is the issue

__________________

1990 Corvette ZR-1 #1051 Watson Headers (2" Primary) - Flowmaster Cats - Borla Catback Late Model IH - Plenum Coilovers - 4.10s Shelby Series 1 - Wilwood Brakes Custom Interior NCM Lifetime Member #978 |

|

|

|

|

|

#26 | |

|

Join Date: Oct 2005

Location: Candy Apple...yUmMy

Posts: 1,137

|

Quote:

|

|

|

|

|

|

|

#27 |

|

Join Date: Oct 2005

Location: Candy Apple...yUmMy

Posts: 1,137

|

|

|

|

|

|

|

#28 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,180

|

It seems to me the tool is only needed to locate the proper hole, which I believe they state is at about 51 degress BTDC. The hole for cam timing is deeper that the others, and the pin tool drops flush in the proper notich. I would think that one could use a measured dowel to accomplish the same running a few rotations to ensure that you chose the correct notch.

LGAFF 92 ZR1 #234 |

|

|

|

|

|

#29 | |

|

Join Date: Oct 2005

Location: Candy Apple...yUmMy

Posts: 1,137

|

Quote:

|

|

|

|

|

|

|

#30 | |

|

Guest

Posts: n/a

|

Quote:

So you are forcing roughly 160+ ftlbs of pressure on the crank reluctor wheel? |

|

|

|

|

|