|

|

#41 | |

Join Date: Jul 2010

Location: Woodstock, Ontario, Canada

Posts: 1,271

|

Quote:

http://www.csgnetwork.com/fiflowcalc.html Gets exactly the same numbers you get. Stock flow=20.5 Fuel pressure used for rating the injector=43.5(3BAR) Actual rail pressure(unreferenced) 50.76 psi Gives me 22.1 b/hr of fuel at the fuel pressure the injector will actually be used at. 22.1 lb/hr converts to 2.78 g/sec 22.78lb/hr converts to 2.87 g/sec Never seen seconds per grams before, but it all converts to the same nomatter the unit. |

|

|

|

|

|

|

#42 | |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

Quote:

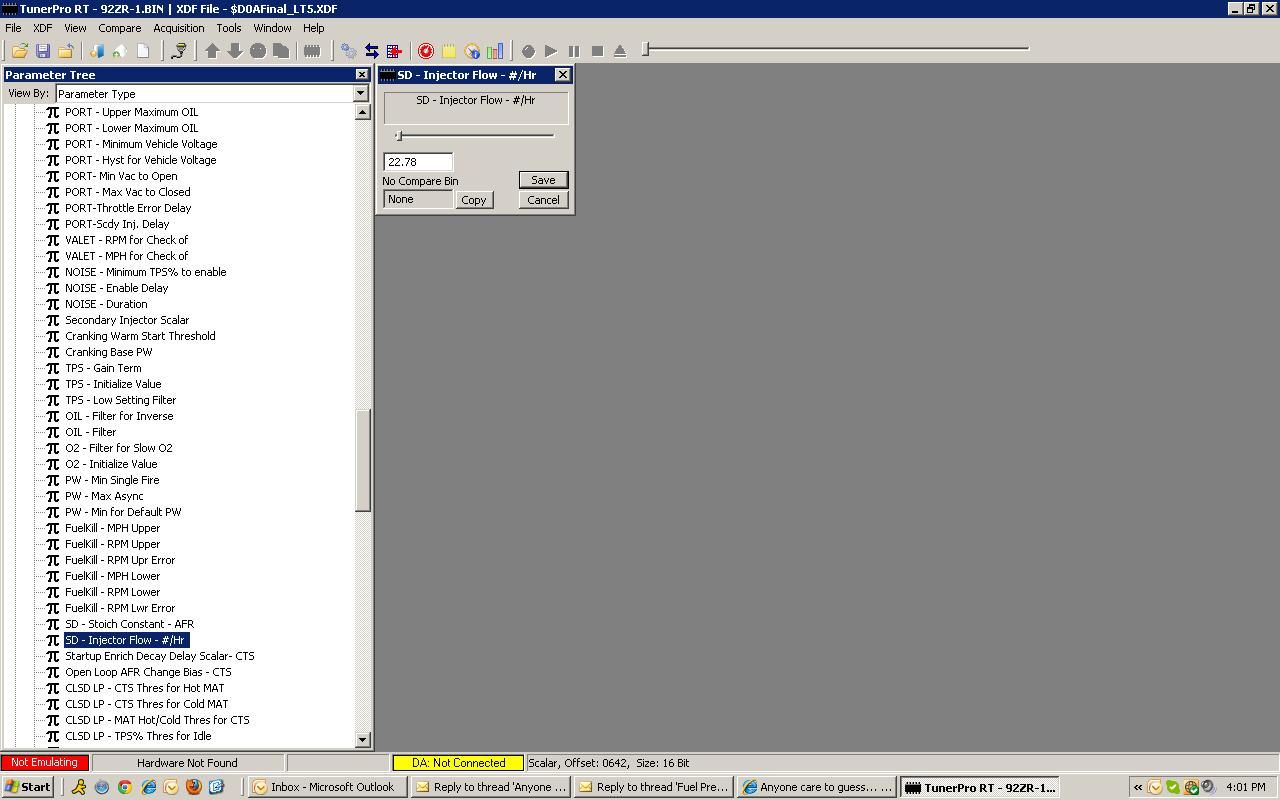

I would focus more on the correct injector offsets for non-stock injectors like the Accels as an example. What you may want to try, for grins, is to note what kPa your motor idles at, say between 50-55kPa or ~ 15.5" Hg. Throw on a fuel pressure gauge, attach a Mighty Vac with a gauge onto the fuel regulator, turn ignition on, and the apply 15.5" Hg. See what your FP is. Vary the vacuum and see what happens. I had to do that w my Xfire while using a VAFPR to manage fuel flow based on load. I had to calculate what the BPC was for each 5kPa increment and fill a table so the ECM was using the correct BPC based on load. With a modded TBI system, it was the only way to have enough fuel flow at WOT, while still being able to control idle. Below is a screen shot from TPRT of the fuel flow found in the AYWT bin for a 92 LT-5.

|

|

|

|

|

|

|

#43 |

|

Join Date: Aug 2005

Location: Fishers, IN

Posts: 813

|

It is *differential* pressure that the FPR attempts to maintain. Differential meaning the pressure on the inlet side of the injector versus the outlet (manifold) pressure.

As you get closer to WOT, manifold vacuum approaches zero, thus the injector sees ~51psi differential pressure from the regulator. As seen with the vacuum reference line disconnected. Less than WOT, the FPR reduces fuel pressure on the inlet to the injector because you now have a vacuum on the outlet side. Say you are idling at 8 psi vacuum. To achieve 51psi differential pressure, the FPR reduces the supply to 51-8=43psi. The injector behaves (flows) the same as it does with 51psi rail pressure at WOT. At least that's how I understand it.... |

|

|

|

|

|

#44 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

Todd,

Think of it this way. At high vacuum, ie idle, fuel is being literally sucked out of injector. At WOT or very close to 100kPa, getting the fuel into the airflow takes more pressure therefore a 1:1 VAFPR to maintain the same amount of fuel flowing whether #/hr or gms/sec. In TBI systems the injector is always exposed to atmospheric pressure. Getting fuel into the airflow is a question of "shearing" the fuel off the Venturi walls as the air rushes by in order to atomize it. But TBI systems run at maybe 10-14psi. Atomization is where direct injection really shines due to the much higher pressures. |

|

|

|

|

|

#45 | |

Join Date: Jul 2010

Location: Woodstock, Ontario, Canada

Posts: 1,271

|

Quote:

In newer MPFI systems that dont use any sort of FPR, this is all the pressure differential across the injector is calculated by the PCM at differnt MAP points. |

|

|

|

|

|

|

#46 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

I recall hearing that the ZR no hyphen 1 varied its fuel flow elctronically in 3 stages. That way they could use 8 injectors to support 638hp, but still have a pulsewidth that was controllable for idle and emissions. Are current MPFI systems now Speed Density, MAF, or a combination?

|

|

|

|

|

|

#47 |

Join Date: Jan 2009

Location: Mandeville, LA

Posts: 340

|

Dom,

The LS stuff I'm fooling with now is blended MAF/Speed Density. The PCM uses both measured airflow from the MAF and speed density calculated airflow. The PCM blends these in different proportions based on load. It also does cross checks and will set a code if MAF and speed density airflows don't correlate within a given percentage. Jep |

|

|

|

|

|

#48 | |

|

Join Date: Dec 2012

Location: NC

Posts: 1,783

|

Quote:

Seems then that the P1 value, as Hog posted, is CRITICAL, not only in theory, but in PRACTICE, because the P2 ADJUSTED pressure is dependent on a SPEC ZERO'ed reading. Quote:

Isn't this correct? Last edited by Schrade; 09-26-2013 at 11:58 PM. |

|

|

|

|

|

|

#49 | |

Join Date: Jul 2010

Location: Woodstock, Ontario, Canada

Posts: 1,271

|

Quote:

A card style MAF is used along with MAP inputs. This would be a combination style setup. I just went through a modern 2012 calibration and man its heavy, literally thousand and thousands of parameters. |

|

|

|

|

|

|

|