|

|

#41 |

Join Date: Dec 2003

Location: Arcadia, OK

Posts: 3,401

|

It's a pull-release clutch, not a push-release, hence the "ball" surface on the underside of the pivot, where the load is.

__________________

Jerry Downey JERRYS LT5 GASKETS & PARTS http://www.jerrysgaskets.com 1994 ZR-1, Black/Black, Lingenfelter Aerobody, 416cu in, 3.91 gears, coil-over susp, Brembo brakes, etc. 2016 Black-Red, 3LT-Z51 Auto 8-speed. |

|

|

|

|

|

#42 | |

Join Date: Dec 2012

Location: Chester, Virginia

Posts: 457

|

Quote:

Lance...red/red 1991 0682 |

|

|

|

|

|

|

#43 |

Join Date: Apr 2007

Location: Lake Bluff, IL

Posts: 2,143

|

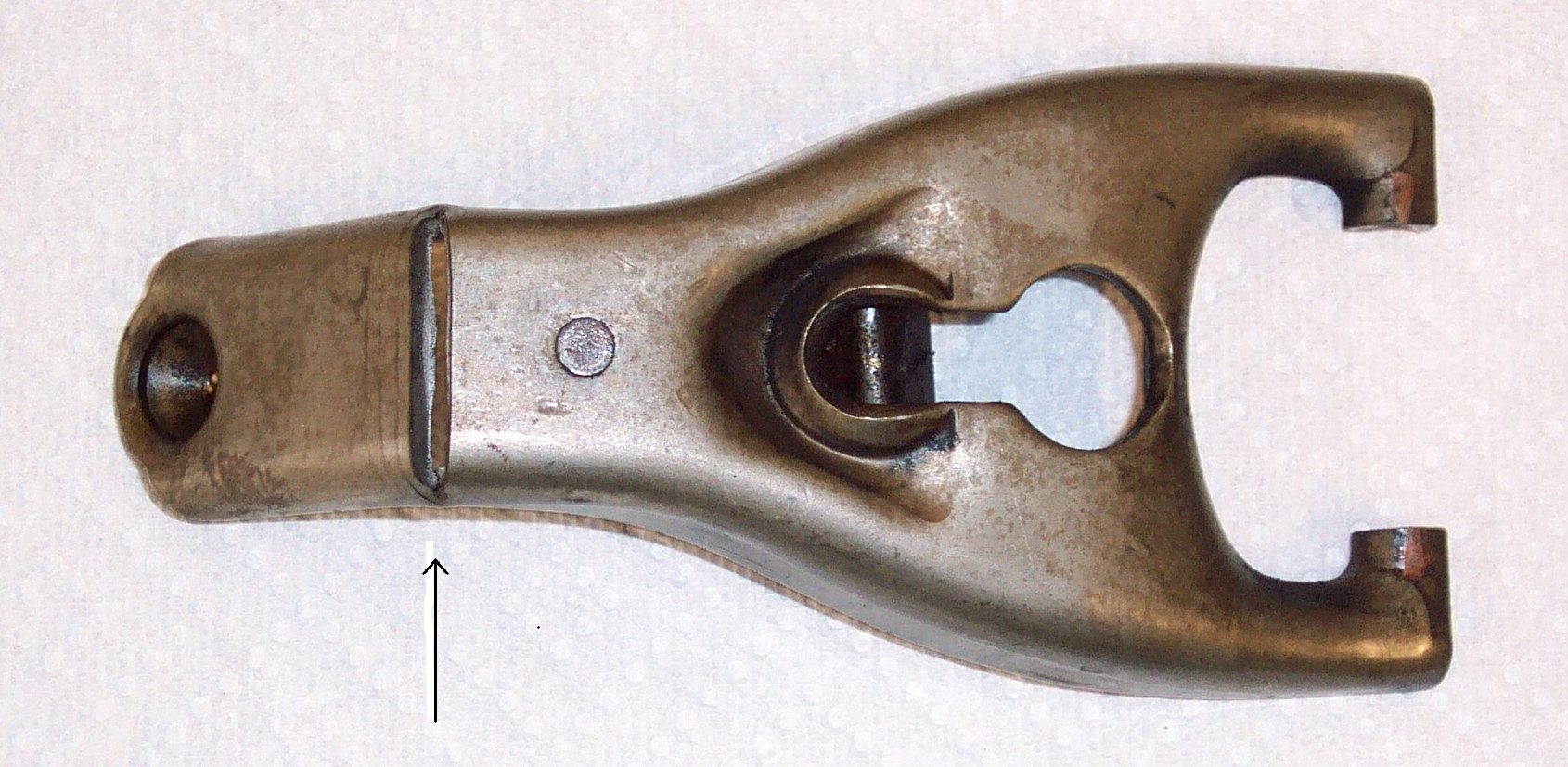

I was looking at Marc Haibeck's website and saw he has a clutch fork failure mentioned, but it broke at a different point due to lack of lubrication. So I am not sure what will show when we are looking at a fork to anticipate possible failure. Here is what he showed and said :

This fork broke because it was subjected to high load during many clutch release cycles. It was used with an OE type Valeo pressure plate.

The root cause was lack of lubrication on the pivot ball. The pivot ball was dry with no lubricant. The pedal force required to release the clutch was about twice the normal amount. With a new fork and a lubricated pivot ball the pedal force to release the clutch returned to normal. The correct pivot ball lubricant has a molybdenum disulfide high pressure anti-friction additive. The pivot ball should be freshly lubricated when a new clutch is installed. The tips that engage with the throw out bearing should also be lubricated.

__________________

2016 Long Beach Red Z06 #10281 "POPS Z" 1995 Polo Green #409 "WARP TEN"--Haibeck 350/510 package, 4.10s, Hurst, Stock Exhaust with QTP Cutouts --Sold but still running strong 1993 Quasar Blue #161 "HIL KING" --Sold but still running strong, now with more than 120,000 miles 1967 Marlboro Maroon/Saddle Corvette Coupe 300 hp/4-spd --Sold a long time ago ZR-1 Net Registry Founding Member #95 NCM Lifetime Member Favorite Quote--Attributed to Mickey Thompson: "Too Much Horsepower is Almost Enough" |

|

|

|

|

|

#44 |

Join Date: Dec 2012

Location: Chester, Virginia

Posts: 457

|

Interesting that it broke along what may be a forming score line.....

|

|

|

|

|

|

#45 | |

Join Date: Aug 2006

Location: McLean, VA

Posts: 3,730

|

Quote:

May I sit in your car and reminise? I'll be back in 1991! |

|

|

|

|

|

|

#46 |

Join Date: Dec 2003

Location: Arcadia, OK

Posts: 3,401

|

Virtually all fatigue breaks occur at stress risers, i.e. nicks, scratches, sharp corners, tooling marks, etc. That's why parts designed to shear at specific axial load pressures are polished.

This get me to thinking about "weak links." The cause of fork failure sure points to excessive pivot friction. if the clutch fork was strengthened and excessive pedal pressure ignored, eventually the pivot would break or wear to the point the fork would come off the pivot. I'm not sure what exactly might happen, but it could be much more catastrophic if the fork got tangled up in there. The moral of the story is check the pivot, check fork, replace if worn and lubricate always.

__________________

Jerry Downey JERRYS LT5 GASKETS & PARTS http://www.jerrysgaskets.com 1994 ZR-1, Black/Black, Lingenfelter Aerobody, 416cu in, 3.91 gears, coil-over susp, Brembo brakes, etc. 2016 Black-Red, 3LT-Z51 Auto 8-speed. |

|

|

|

|

|

|