|

|

#61 | |

Join Date: Aug 2005

Location: Fishers, IN

Posts: 812

|

Quote:

Ryan is right...SpeedTalk forums rock. I've learned a ton from those guys. I am making a polyurethane port mold of my heads & housings today, just to get a better idea of the shape and area throughout. The inside mic shows a min cross sectional area not much bigger than the stock casting. This A-B test you guys are talking about would have to include swapping both heads and housings and plenum. It all needs to work together. Huge port heads on small port housings would not be a fair comparison, and vice versa. I would offer my stuff for such a test, but it would be tough to just bolt on to someone else's motor. Valve stem heights are different, lifters are different, cams, and so on. Can't discount the need to tailor the cam profile to the port velocity either. That was a primary input into the lobe profile (ie, flow at different lifts, and port velocity). Good stuff guys.  Todd |

|

|

|

|

|

|

#62 |

Join Date: Jan 2006

Location: Niceville

Posts: 1,000

|

Man, you guys are awesome! I would be dangerous with time and money.

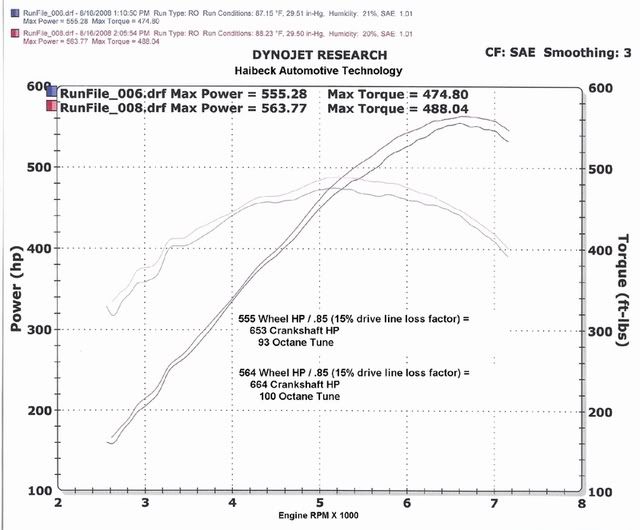

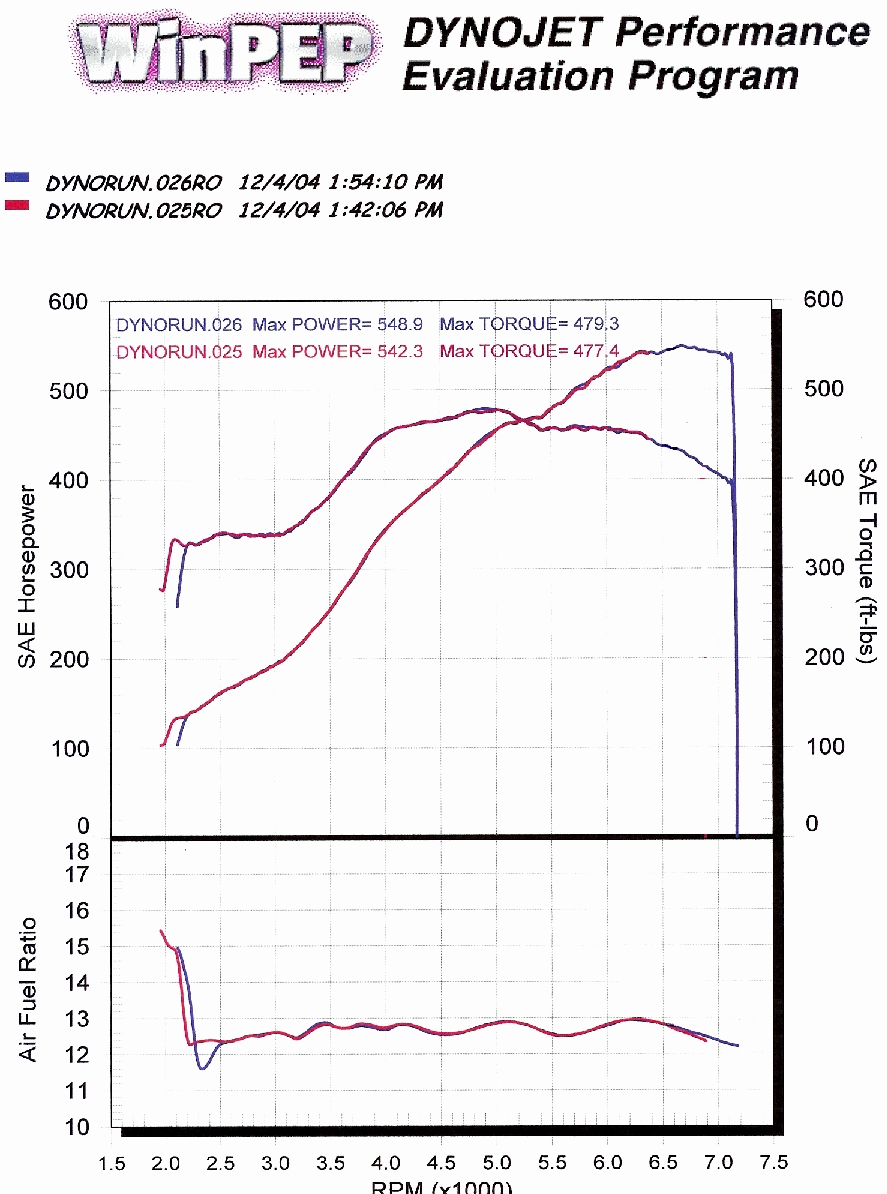

One thing I desired (when I wussed out and paid someone else for the mod) was area under the [power] curve. My 415 made more power down low (with LPE B cams-->smaller exhaust) than dyno's I've seen with Stg III cams. My car is not the most powerful and I have not had a chance to track it yet but it pulls very well. I did not go with bigger valves for $ vs gained when it came down to that vs eating. Scales are different on the two graphs but... My car:  Cam'd 415 Marc did (from his site):  I'm not a dyno bench racer by any means...just proud to have what I have and learn more from the smart folks. |

|

|

|

|

|

#63 |

Join Date: Aug 2006

Location: Edmonton, Alberta or Phoenix, Arizona

Posts: 2,736

|

|

|

|

|

|

|

#64 |

Join Date: Nov 2008

Location: Grand Rapids, MI

Posts: 382

|

I think those two dyno charts makes a good point about what you want the motor for. As Demps said, he wanted more power under the curve or what I assume is a very streetable power band. The second motor made much less hp at 3500rpm and didn't make the big number till much higher in the rpm range; maybe it's used as a race motor and sees high rpms quite often.

I asked Marc H about a 385 with stage 3 cams and this was his response: "I dyno'ed a 385 with SGC Stage III cams that a customer brought in. I was able to tune it to 503 whp. That's 593 crankshaft hp. Torque at 3500 rpm was 325 at the wheels. The engine was way over cammed. The idle was very rough. 3500 rpm is an important speed if the car is driven on the street. Compared to my 385 package with stock cams the engine had -65 torque at the crankshaft. I don't think that the torque loss is worth getting the additional 28 chp. The most cam that I would recommend is Stage II intakes and stock exhaust cams." Back to topic.....tpepmeie, are you going to reveal your cam specs?

|

|

|

|

|

|

#65 |

Join Date: Aug 2006

Location: Edmonton, Alberta or Phoenix, Arizona

Posts: 2,736

|

My exact feelings as well, only way to do it. Everything 'Starts' at the valve seat.

|

|

|

|

|

|

#66 | |

Join Date: Aug 2006

Location: Edmonton, Alberta or Phoenix, Arizona

Posts: 2,736

|

Quote:

|

|

|

|

|

|

|

#67 |

|

Join Date: Sep 2006

Location: lone pine and mammoth lakes

Posts: 1,406

|

i understand the need for a complete setup ie heads inj housings and plenum. i was just offering to see what different porting on inj housings and plenum on a basicly stk motor . what i have decided inon doing is 2 different tests. 1 testing the stainless works headers and corsa exhaust that is currently on the 92 .then changing it out for the jeal headers and dr gas spin tech set up that is on the 90. then changing out the ported stuff off my 90 onto my 92 . famoso has 2 ,2 day sessions consecutive . weekends . wekend one will be the exhaust and weekend 2 will be the injector housings and plenum . am going to bill bs. next week to have a new clutch setup put in as i hope to make 10-15 runs each weekend .so for the hijack . i really like the thought of the smaller contured ports to make power .

|

|

|

|

|

|

#68 | |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,683

|

Quote:

He also recommends that minimum valve lift be 25% of valve diameter. This produces an unobstructed "window" for the airflow past the valve head. His article(s) that I read were directed to 2 valve Chevy heads. Last edited by XfireZ51; 01-18-2010 at 12:59 PM. |

|

|

|

|

|

|

#69 |

Join Date: Dec 2003

Location: Chicagoland,IL

Posts: 2,667

|

Oh boy now we went to cams.

Did some testing there also. Well here are some findings on 421ci with SGC Stage II's these are Intakes .237 .440 Exhaust .237 .440. We changed the exhaust cam with a .224 .425 car picked up 10-20+ thru the curve with gains at peak. I never said bigger is better. I never tested a 34mm or 35mm ports maybe they will make same HP as 36mm somebody do it and let me know. I have tried bigger 38mm fully siemesed plenum/IH's with no gains this was on my 350. I really think big inch motors would benefit from big siemesed & dropped plenum /IH's On the above Dyno sheets it's not like the 415 making 350rwtq at low rpm is going to drive like a slug down the street. Pete

__________________

'91 #1635 PoloGreen 350 LT5 11.09 @ 129.27 11.04 @ 128.86 474RWHP 400RWTQ http://www.youtube.com/watch?v=SFNFOhGGlR4 http://www.youtube.com/watch?v=ZlRIOMwaDYY https://sites.google.com/site/peteszr1garage |

|

|

|

|

|

#70 | |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,683

|

Quote:

I think my point and I believe Todd's point is how interrelated port flow and cam timing events are. In the effort to optimize/maximize the results, (and this isn't new stuff) the cam needs to take maximum advantage of the airflow made available through the induction system and the heads. Too many times people choose the cam first without much regard to the cylinder head design and flow characteristics. |

|

|

|

|

|

|

|