|

|

#21 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

Pulled both IHs to discover some oil seepage, like ccmano, from PCV vents into cylinders. I did not realize that only two of the three apparent vents are functional on the cylinder heads. These pics are of both sides IH. The first being right side, but left side also showing some seepage. We see seepage into middle cylinders on each cylinder head. I also show the #6 cylinder plug as it correlates to the seepage we see on the Ih gaskets.

Last edited by XfireZ51; 03-08-2024 at 02:09 PM. |

|

|

|

|

|

#22 |

Join Date: Jul 2012

Location: Allentown, PA

Posts: 308

|

Looks like an oil control problem. I don't recall the details, but didn't you have some repairs done to the top end a year or so ago? Were the valve seals disturbed? Are those your original IH's? Are yours supposed to have plugs in the crankcase ventilation ports?

Sent from my HTC U11 using ZR-1 Net Registry mobile app

__________________

'95 ZR-1, aqua/gray, #167 368 LPE/Haibeck, Web cams, Stainless Works headers, B&B Fusion exhaust, 18" Fikse wheels, Alcon brakes, lowered. 491 SAE RWHP. |

|

|

|

|

|

#23 | |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

Quote:

Had a compression ring that cracked on #7 which Pete R&R’d. Yes original IHs.The crankcase vents match up w the heads. Last year we thought that may have been the issue w my oil usage but it turned out to be a broken compression ring. I think I documented it on forum. |

|

|

|

|

|

|

#24 |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

I've experienced the 'lean but rich' dilemma before. (It lead me to my purchasing a scanner which ultimately identified the problem.)

Anyway.... When I got a lean BLM, the PW went wide and the plugs were a dry, flat black sooty coated in appearance. In your photos, is the one of the spark plug totally unmolested? I ask because there is a definite shine in the photo on the edges of the insulator and the ground strap too. That is very uncharacteristic of rich. If unmolested (e.g.,accidentally wiped or brushed against something), it looks to be a little more like either oil or antifreeze???? Lean but rich: Air diluting the exhaust seen by the sensor Failing O2 or connector to the ECM An error in the tune Shiny black (wet): Oil Antifreeze (the pix of the gasket suggests less than perfect seal) Plug heat range too low Checked your oil catch can recently? Checked your antifreeze level over time (mileage)?

|

|

|

|

|

|

#25 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

Thx Paul. Based on what I see w gaskets, its oil getting in there.

|

|

|

|

|

|

#26 |

|

Join Date: Jun 2006

Location: Sparks, NV

Posts: 2,843

|

Looks identical to what I found when I pulled my old high mile engine. In my case I am convinced it was due to age and mileage which resulted in the hardening of the gaskets and loosening of the IH bolts. That engine was burning considerable oil as a result. In this case it may simply be the result of reuse of the IH gaskets when the previous engine work was done, which I believe was the case. Generally, once gaskets are compressed they never again have the same sealing properties if used multiple times. Dom has done considerable data logging on this engine. Had there been a manifold/crankcase pressure issue it should have shown itself in the MAP sensor readings, which, as I understand, was not the case.

After researching my issue and now this one I am of the opinion that this condition is much more common than we think. Several factors come into play. Loose IH bolts is a known issue. Age, mileage and the resultant heat cycles harden the gaskets and loosen the bolts. The design, with crankcase oil vapor galleys, coolant passages and intake runners in close proximity, with only a thin gasket to seal, is not ideal. Generally, IH gaskets are not high on the list when “top end” work is done. IH’s are not generally removed unless more major work is done. Even then no one pays attention to the IH gaskets. In this case I would simply replace the gaskets, reassemble and (blue) loctite the IH bolts, then monitor crankcase/manifold pressures. H

Last edited by Ccmano; 11-13-2018 at 11:23 AM. |

|

|

|

|

|

#27 |

Join Date: Dec 2003

Location: Arcadia, OK

Posts: 3,404

|

Three important step for proper gasket sealing.

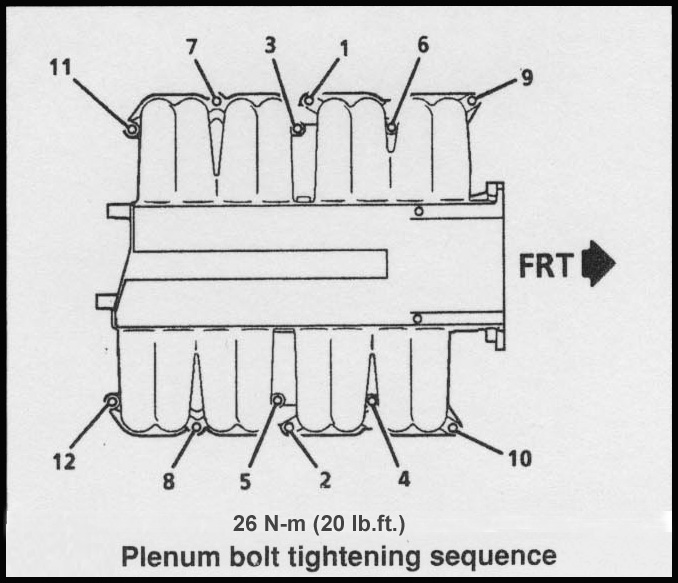

1. Insure gasket mating surfaces are completely cleaned and free of any oil residue which will impede gasket sealing 2. Check & insure the mating surfaces are perfectly flat. The gasket material we use is very high quality. Compressibility is 12~15% of the un-compressed thickness. Translated to real numbers, a 1/32" (0.03125") gasket will compress appx 0.004". Using this value as a guide, flatness should be held less than 0.002" A precision straight edge and feeler gauge are recommended. 3. Proper torquing sequence. The general rule of thumb is to start at the middle & work towards the ends in a x'ing pattern. My personal technique is to make 4 passes, #1 @ 1/3 of the full torque value, #2 @ 2/3, #3 @ full torque and the last pass again @ full torque. True surfaces and proper technique don't require thick gaskets. For EACH Injector Housing with staggered bolts, follow the same torque pattern concept as shown for the Plenum.

__________________

Jerry Downey JERRYS LT5 GASKETS & PARTS http://www.jerrysgaskets.com 1994 ZR-1, Black/Black, Lingenfelter Aerobody, 416cu in, 3.91 gears, coil-over susp, Brembo brakes, etc. 2016 Black-Red, 3LT-Z51 Auto 8-speed. |

|

|

|

|

|

#28 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

Jerry,

Thx. That was going to be one of my questions. And I have been told that its better to use the thinner gaskets for clamping and sealing. |

|

|

|

|

|

#29 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

Concurrently, w the contradictory BLM v spark plug readings, I have been chasing what was going on w getting knock counts during times of steady cruise and at a fairly specific area of the VE and SA tables. Been wary of this ever since I had the issue w a broken compression ring on #7 last year. Every thing I had read pointed towards knock being th cause. Turns out I could induce Knock and Retard by stabbing the throttle. Knock shows up both on the opening and closing of the throttle. I have been thinking that I needed to beef up the AE pumpshot. Meanwhile, I had continued to reduce timing and seeing a reduction in the knock counts. However, timing was getting to where it was at “stock” levels and there was still some knock showing up, at times with literally no changes happening in driving conditions, ie tps%, MAP, SA etc. It would just show up for just a few frames. Another ZR that I have been tuning had no knock w timing significantly higher than my own. Seeing the oil seepage into at least a few of the cylinders has me concluding that the knock and the plug coloration due to oil seepage are related. Oil has a lower detonation point than 93 Octane and has been costing me some spark advance. I have replaced the knock sensor as one of the those

“While u r there things” since I have no idea how long its been there and its inexpensive enough to swap it out. |

|

|

|

|

|

#30 | |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

Quote:

Did both heads come off to inspect the motor as well as replace the parts related to the broken ring? - seems curious you'd have a leaking gasket(s) issue a year after they were (presumably) replaced, no? |

|

|

|

|

|

|

|