|

|

#11 |

Join Date: Jan 2004

Location: Portland, OR

Posts: 1,057

|

Sounds like you are being way too aggressive with the cutting bits if you are punching through that fast. I like to switch back and forth between cutting bits and sanders throughout the process - helps with keeping the dimensions even and the work consistant. I'll work a runner with a bit for a minute or so then try to do the same thing to others. Then I use a sanding drum to smooth out the surface. After that I measure the worked areas with a telescoping gauge to see where I'm at. Rinse and repeat.

You should be concentrating on the short side radius of the curve - not the outside. You want to straighten out the curves as much as possible. It's also an easier fix if you go through on the underside as you don't have to clean up the welds perfectly.

__________________

Robert ZR-1 Net Registry Oregon State Director 91 ZR-1 #431 Black/Black LPE 368 |

|

|

|

|

|

#12 | |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,493

|

Quote:

Thanks for the input! (And I do have some snap gauges that I'll put to use!) P. |

|

|

|

|

|

|

#13 | |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,493

|

Quote:

As far as maintaining the centerline throughout, with the exception of the first couple of runners, I'm actually attempting to straighten the line a bit - more to avoid getting too close to the outside radius, as much as anything. I figure that (within reason) nothing on the plenum can't be filled and re-ground if necessary. So, except for a couple of initial "boo boos", it hasn't been bad at all (and getting better!). First time for everything, and I have 16 "tries" to break out of rookie status before I move onto the IH. It's coming together now, and I don't feel the least bit intimidated...yet. P. |

|

|

|

|

|

|

#14 | |

Join Date: Dec 2003

Location: Chicagoland,IL

Posts: 2,679

|

Quote:

Yeap,that's it with what flyin ryan said single cut. Ryan thanks for info and part # need to get a new one. Elk Grove is next town over from me.  Pete

__________________

'91 #1635 PoloGreen 350 LT5 11.09 @ 129.27 11.04 @ 128.86 474RWHP 400RWTQ http://www.youtube.com/watch?v=SFNFOhGGlR4 http://www.youtube.com/watch?v=ZlRIOMwaDYY https://sites.google.com/site/peteszr1garage |

|

|

|

|

|

|

#15 | |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,493

|

Quote:

Much as I hate Chicago (or any big city, for that matter - congestion and traffic and crowds n all, and did I mention traffic?), the outlying areas in N. IL are a Mecca for ZR-1'ers. Buncha hard core Z drivers up there! P. |

|

|

|

|

|

|

#16 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,193

|

I am using a gasket set to center as well, I know it may not be ideal, but when you measure the stock ports there is a wide variation to ports size, etc. I measured the primaries on the current set I am working on at the head surface and they varied from 31.25 to 32.7MM.

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 Last edited by LGAFF; 02-23-2009 at 08:13 AM. |

|

|

|

|

|

#17 |

Join Date: Dec 2003

Location: Arcadia,OK

Posts: 3,393

|

Gasket is good if it's OEM (or mine:wink) only saying that because those are the only ones I am certain that are made to spec. Others may be copied from gaskets.

In addition to port dia variance, there is core shift in the castings so ports often to not center in the gasket, as you have probably noticed. It is a tedious job! My hat's off to you!

__________________

Jerry Downey JERRYS LT5 GASKETS & PARTS http://www.jerrysgaskets.com 1994 ZR-1, Black/Black, Lingenfelter Aerobody, 416cu in, 3.91 gears, coil-over susp, Brembo brakes, etc. 2016 Black-Red, 3LT-Z51 Auto 8-speed. |

|

|

|

|

|

#18 |

|

Join Date: Oct 2005

Location: Candy Apple...yUmMy

Posts: 1,137

|

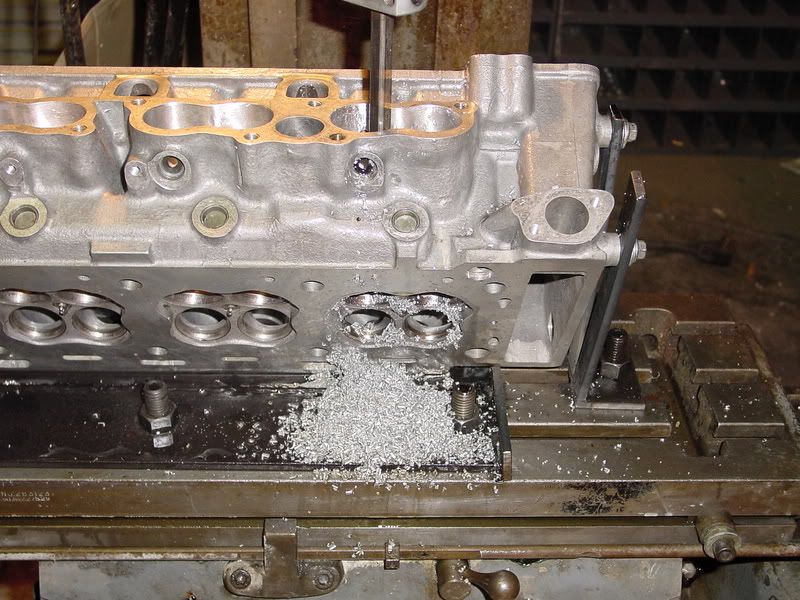

You need a Bridgeport.....makes porting a snap!

|

|

|

|

|

|

#19 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,700

|

Be still my heart.

|

|

|

|

|

|

#20 | |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,493

|

Quote:

(OSG) 906-6250, SE-6 5/8" dia. x 1" long, oval, fine (single) cut flute, standard 2" shank @ $19.68 ea. SE5L6 = 1/2" dia x 7/8" long, oval, fine (single) cut flute, 6" shank, @$24.90 ea. These appear to be very nice, well made tools! (I'll put them to the test today.) With that I got both the OSG and Fleetwood catalogs - great reading. FYI, P. Last edited by Paul Workman; 03-01-2009 at 06:28 AM. |

|

|

|

|

|

|

|