|

|

#1 |

Join Date: Dec 2012

Location: Ponoka, Alberta, Canada

Posts: 158

|

In the "Dreaded No Start" Thread, I had asked about the misalignment on the secondary Actuator linkage as found on My 91.

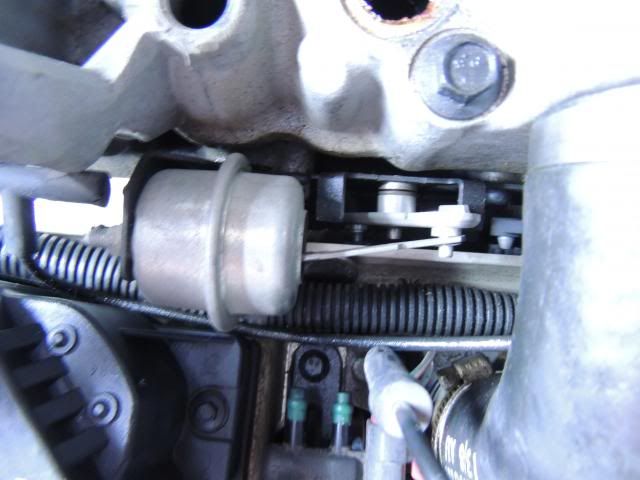

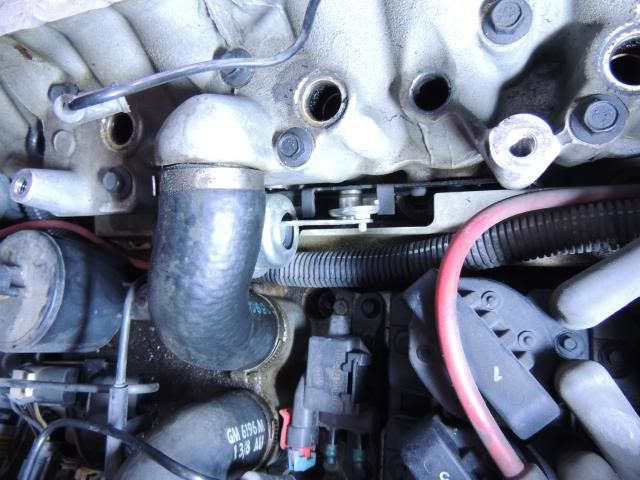

Linkage as found  To Me it appears that it would cause binding of the linkage and abnormal stress to the diaphragm. So I removed one and tested both with a vacuum testor, neither appeared to bind in any way, and the vacuum required for full travel was the same on each one. Actuator rotated 180 deg to straighten alignment.  I gather there are differing opinions regarding which is the correct mounting.

__________________

91 ZR-1 Arctic White/Gray 01 C-5 Magnetic Red/Black 85 FJ 1100 (Big Bore kit, Hooligan Bike) 05 FJR 1300 Yamaha (Long Distance, Sport Touring) And a whole whack of RC Planes |

|

|

|

|

|

#2 | ||

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,799

|

Quote:

That is what I found also....... but what appears below is actually an incorrect installation (Not angled shaft). However, this incorrect installation seems to work fine (using New Canisters)......which when I get back to the 90' I will verify one more time. Secondary Canister Installation Secondary Canister Installation FACTS TIPS This Canister Installation (New Canisters) would be wrong but I will check operation as I can pull Plenum in 10 minutes   I have modified Canisters in the past by filing just a tad on the arm edges where they might bind with the Canister opening.   Quote:

__________________

Left Clickable links -Solutions- LT5 Modifications/Rebuild Tricks Low Mileage ZR-1 Restoration 1990 Corvette (L98) Modifications LT5 Eliminated Systems LT5 Added Systems LT5/ZR-1 Fluids 1995 LT5 SPECIFIC TOP END REBUILD TRICKS Last edited by Dynomite; 12-12-2013 at 11:40 PM. |

||

|

|

|

|

|

#3 |

Join Date: Dec 2012

Location: Ponoka, Alberta, Canada

Posts: 158

|

Dynomite, I had seen your pictures previously, ( Thanks for all your solutions threads, I have read quite a few so far.)

The angle of your picture made it hard to tell which orientation yours are in. So I thought I would take a couple more square on to illustrate the difference.

__________________

91 ZR-1 Arctic White/Gray 01 C-5 Magnetic Red/Black 85 FJ 1100 (Big Bore kit, Hooligan Bike) 05 FJR 1300 Yamaha (Long Distance, Sport Touring) And a whole whack of RC Planes |

|

|

|

|

|

#4 | |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,799

|

Quote:

Great photos you have in your first post.....thanks  WVZR-1 background information and analysis is appreciated

__________________

Left Clickable links -Solutions- LT5 Modifications/Rebuild Tricks Low Mileage ZR-1 Restoration 1990 Corvette (L98) Modifications LT5 Eliminated Systems LT5 Added Systems LT5/ZR-1 Fluids 1995 LT5 SPECIFIC TOP END REBUILD TRICKS Last edited by Dynomite; 06-16-2013 at 05:42 PM. |

|

|

|

|

|

|

#5 |

Join Date: Dec 2012

Location: Ponoka, Alberta, Canada

Posts: 158

|

As Posted by Jerry;

By request from the OP, Barely Flying, please find the following, FACTUAL information regarding "Secondary actuators installed backwards at the factory"; In actuality, this is simply not accurate. Chris Allen, Assembly Manager and Scott Skinner, Engine Building Supervisor, were Mercury Marine employees on the LT5 project. I am proud to say that both are good friends of mine. I also personally know several of the girls who worked on the LT5 assembly line. My information comes directly from all of the above. The facts are: 1. The linkage arm sits to one side of center due to an "L" bend in the arm for attachment to the actuator diaphram. 2. The actuator was initially installed with the diaphram linkage "straight in line with the secondary linkage bellcrank.Binding/dragging was evident, so the actuator was turned over to align the center of the actuator diaphram with the bellcrank. The linkage was angled but the pull was straight and aligned with the actuator. No more binding, quicker & smoother operation. 3. The LT5 was essentially a hand-built engine produced to race engine tolerances, by Mercury employees who filled voluntary positions with no guarantee that the positions they were leaving, earned by time & performance, would be available to them after the LT5 program was completed. They were a team of highly skilled and motivated personnel. 4. The ocassional posts about "a woman" doing sub-standard work is unfounded and unwarranted. To further promote baseless rumors only serves to promote mis-truths about the LT5 and cast an undeserving bad light on individuals who consider the LT5 program at Mercury Marine in Stillwater, OK, the highlight of their entire career. THE BOTTOM LINE: The actuators work best and are supposed to be installed with the linkage bar angled to the secondary linkage bellcrank, to achieve a straight pull from the diaphram. Do not rotate the actuator to obtain a straight linkage bar. __________________ Jerry Downey JERRYS LT5 GASKETS & PARTS http://www.jerrysgaskets.com

__________________

91 ZR-1 Arctic White/Gray 01 C-5 Magnetic Red/Black 85 FJ 1100 (Big Bore kit, Hooligan Bike) 05 FJR 1300 Yamaha (Long Distance, Sport Touring) And a whole whack of RC Planes |

|

|

|

|

|

#6 |

Join Date: Jan 2009

Location: Portland Oregon metro area (Washington side)

Posts: 3,207

|

OK thanks to the OP in post 1 we see the backward install.

In post #2 we see a correct install. By correct I mean one that does not bind (due to filing the edges of the L bracket) and does not deflect the diaphragm at a angle. Of course anyone can leave the actuators in wrong and justify it by knowing someone at the factory thought it was best but to me the issue is one of root cause analysis. This was NOT done evidently in the factory. Only an expedient solution was used. Root cause would be the excess metal at the short part of the L bracket. (I used a cut off wheel to remove the metal) This is how I solved the problem and have not had sticking actuators since 98. It's good to see others have also come up with this same fix independently. Bottom line there is no need for insults or cheap shots. We can stay on topic and lay out what we know then let all who read choose their solution.

__________________

Scott Vett owner since 1979._It's about the car and the people |

|

|

|

|

|

#7 |

Join Date: Dec 2012

Location: Ponoka, Alberta, Canada

Posts: 158

|

Actually Scott, after reading Jerry's post, I went back and tested the two actuators in their opposite positions, as per my photo's.

WVZR-1 and Jerry are correct, altho the linkage appears to be offset, it is pulling evenly on the diaphragm. I shone a flashlight into the opening around the arm and watched while slowly increasing the vacuum, the diaphragm pulls evenly throughout the stroke. I think what screws with your mind , is the arm moving across the face of the canister as it pulls back, but the distance between the diaphragm and the pivot does not change, therefore the angle will be consistent. I think I will let sleeping dogs lay and keep the original orientation. Thanks for all the insight and suggestions. Don

__________________

91 ZR-1 Arctic White/Gray 01 C-5 Magnetic Red/Black 85 FJ 1100 (Big Bore kit, Hooligan Bike) 05 FJR 1300 Yamaha (Long Distance, Sport Touring) And a whole whack of RC Planes |

|

|

|

|

|

#8 | ||

Join Date: Jan 2009

Location: Portland Oregon metro area (Washington side)

Posts: 3,207

|

Quote:

Think if the short part of an "L" if the long part is slanted then the short part also is. The short part is connected to a flat washer on the other side of the rubber diaphragm. Since the washer is held at the same angle as the crooked L then the rubber is not pulling evenly all the way around. The statement "the diaphragm pulls evenly through out the stroke" is an interesting conclusion. How did you determine this? Did you measure? I know my eyes are just not good enough to see a 1/16in deflection difference. If you release the long part of the L from the ball stud where does the straight part point? Is it still crooked? What would pull it back straight? The deformed rubber maybe? hmmmmm Quote:

Yes, it's bound to work out just fine for you.

__________________

Scott Vett owner since 1979._It's about the car and the people |

||

|

|

|

|

|

#9 |

Join Date: Dec 2012

Location: Ponoka, Alberta, Canada

Posts: 158

|

Scott, I watched the diaphragms as the vacuum pulled back on the linkage, there was no apparent changes to the diaphragm, buckling or stretching that I could observe. No I did not measure anything, I'm not equipped to get that detailed in my garage.

My initial thoughts were that the diaphragm was being stressed by the sideways motion of the arm, but that is not the case as far as I can determine. When the diaphragm first starts moving the arm does move as it centers itself, but it does that in either case, after that the arm moves in a linear path, no sideways movement at all. There is a slight vertical movement due to the arc of the bellcrank, but again it is the same in either case. If there is anything else you can think of to test, I have everything exposed now.

__________________

91 ZR-1 Arctic White/Gray 01 C-5 Magnetic Red/Black 85 FJ 1100 (Big Bore kit, Hooligan Bike) 05 FJR 1300 Yamaha (Long Distance, Sport Touring) And a whole whack of RC Planes |

|

|

|

|

|

#10 | |

Join Date: Jan 2009

Location: Portland Oregon metro area (Washington side)

Posts: 3,207

|

Quote:

__________________

Scott Vett owner since 1979._It's about the car and the people |

|

|

|

|

|

|

|