|

|

#1 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

I heard some horror stories about removing the Oil pressure switch on our motors. Some people would lift the motors up with a hoist others would remove the motor mounts and jack up one side of the motor even read one story or a person removed the exhaust header on that side. Mine was leaking so I decided to take a stab at it. I started from the passenger-side trying to get to it but after a while my hands started cramping from trying to fit in the tight spot at a odd angle. So I step back and took a long look at the situation. I Figured out if you lay a series of blankets over the motor from the drivers wheel over the engine to protect everything and if you lay on top of the engine from the driver side you can reach your left hand in very easily. I also disconnected the oil cooler lines to ease access and plug them with plugs I had in my toolbox, this gives you a few more inches of freedom with the ratchet but it isn't absolutely necessary. Its also nice because with your left hand is in there working you could look right down at the switch through the exposed section. I also dissected the bad switch to see what failed.

Dave

Last edited by mgbrv8; 11-30-2013 at 11:24 PM. |

|

|

|

|

|

#2 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

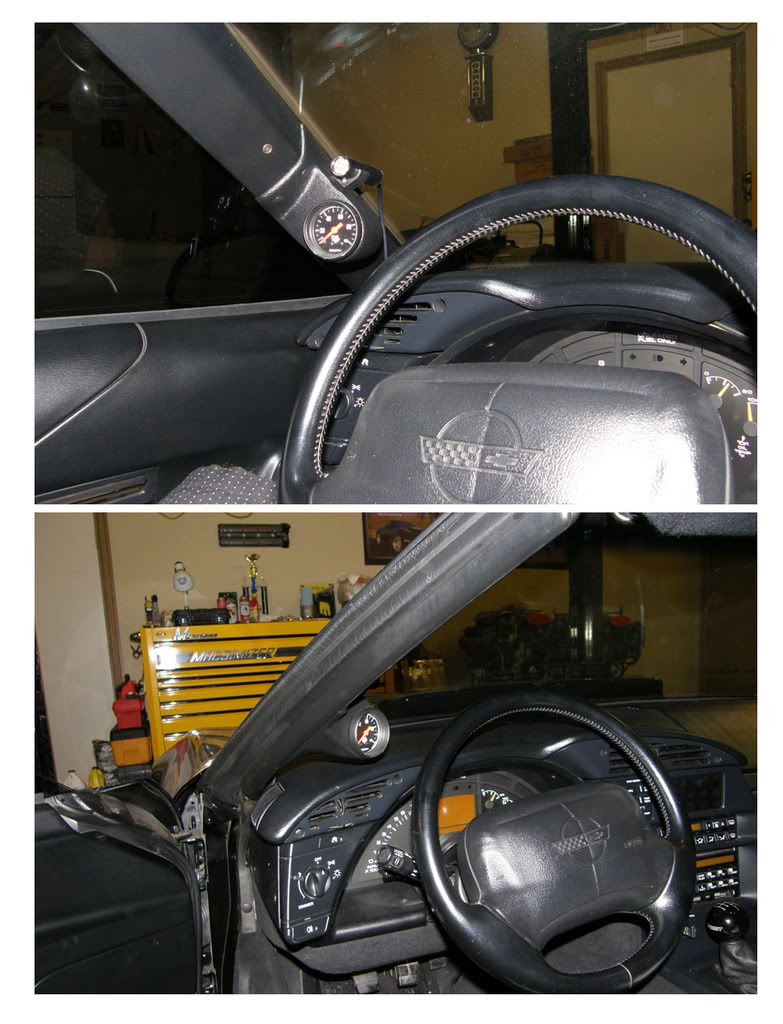

Here are some more pics.

Dave Last edited by mgbrv8; 12-01-2013 at 01:00 PM. |

|

|

|

|

|

#3 |

Join Date: Sep 2013

Location: Charlotte NC

Posts: 654

|

Great Info!

|

|

|

|

|

|

#4 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

Thank you Z06scentair I just want to help our and future members and owners

Dave Last edited by mgbrv8; 11-30-2013 at 11:18 PM. |

|

|

|

|

|

#5 |

|

Join Date: Jul 2009

Location: Texas

Posts: 790

|

I forgot one helpful hint. To keep from straining my wrist while turning the ratchet and trying to hold up the ratchet and socket combination with my fingertips I made a 10 inch length of stainless steel wire with eyelets on each end. I put one eyelet in between the socket and the ratchet head and protruded the other end up through the view port of the oil pressure switch this allowed me to not only hold up the socket against its weight but also to help place the socket on the switch initially. Another point the finer the ratchet the better because you don't have much swing in there. The job in total was about 35min.

Dave

|

|

|

|

|

|

#6 |

|

Join Date: Dec 2012

Location: NC

Posts: 1,783

|

Seems they could have integrated the OP light into the OP guage...

Get Cliff to link it in 'Solutions'... |

|

|

|

|

|

#7 | |

Join Date: Dec 2003

Location: Arcadia, OK

Posts: 3,397

|

Quote:

__________________

Jerry Downey JERRYS LT5 GASKETS & PARTS http://www.jerrysgaskets.com 1994 ZR-1, Black/Black, Lingenfelter Aerobody, 416cu in, 3.91 gears, coil-over susp, Brembo brakes, etc. 2016 Black-Red, 3LT-Z51 Auto 8-speed. |

|

|

|

|

|

|

#8 |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,813

|

OK

Some more information for ya GENERAL CHECKS Post 18 - Engine Oil Pressure/Temperature Sensors Post 19 - LT5 Lubrication Tricks Post 20 - Potential Oil Leaks and the OPRV Cover Plate

__________________

Clickable links On Iphone Touchable Links -Solutions- LT5 Modifications/Rebuild Tricks Low Mileage ZR-1 Restoration 1990 Corvette (L98) Modifications LT5 Eliminated Systems LT5 Added Systems LT5/ZR-1 Fluids 1995 LT5 SPECIFIC TOP END REBUILD TRICKS Last edited by Dynomite; 12-02-2013 at 03:22 PM. |

|

|

|

|

|

#9 |

|

Join Date: Jul 2013

Location: Alabama

Posts: 59

|

This is my kind of thread.

|

|

|

|

|

|

#10 |

Join Date: Apr 2012

Location: Austin, TX

Posts: 54

|

Like many folks my car developed a sudden oil leak which I at first thought was the oil temperature sender and Pete made two good repair procedure suggestions - remove the passenger wheel and the center section of the wheel well liner. But once I removed the wheel and the wheel liner section and started to clean up the sprayed oil it was clear the cause was the oil pressure switch rather than the sender and searching the forum I found folks divided on whether the better approach to replace the switch was to remove the oil filter adapter or to raise the passenger side of the engine. Then I read Dave's procedure.

I have to admit I've done some unusual things in caring for my cars (and trucks and motorcycles) over the years but lying on them is a new one. Still it did make sense to help get one's left hand in a more natural and useful position, although removing the wheel goes a long way toward that same goal (of course all this assumes small hands as without removing hoses the space is limited). And I was already using a variant of Dave's stainless steel wire suggestion. But what really helped was seeing the picture of Dave's tools and particularly his flex head 3/8" socket driver. As the saying goes "use the right tool for the job" and indeed the flex head made all the difference in the world. Unlike Dave I didn't yet have my replacement switch so I couldn't quickly button it up and total my time spent. Plus having removed the wheel and center section of the wheel well liner and done a lot of cleaning my time on the clock was much longer than his. But the important thing is result. And I now know that even if my new switch fails sometime down the road replacing it by removing the passenger wheel and the center section of the wheel well liner, using a helper wire to support the heavy socket with a flex head 3/8" socket driver is a doable task. So thank you, Dave. John |

|

|

|

|

| Thread Tools | |

| Display Modes | |

|

|