|

|

#11 |

|

Join Date: Apr 2009

Location: Prather, CA

Posts: 809

|

(I tried to post this update yesterday at the same time I posted on the "other" forum, but couldn't get this forum to load)

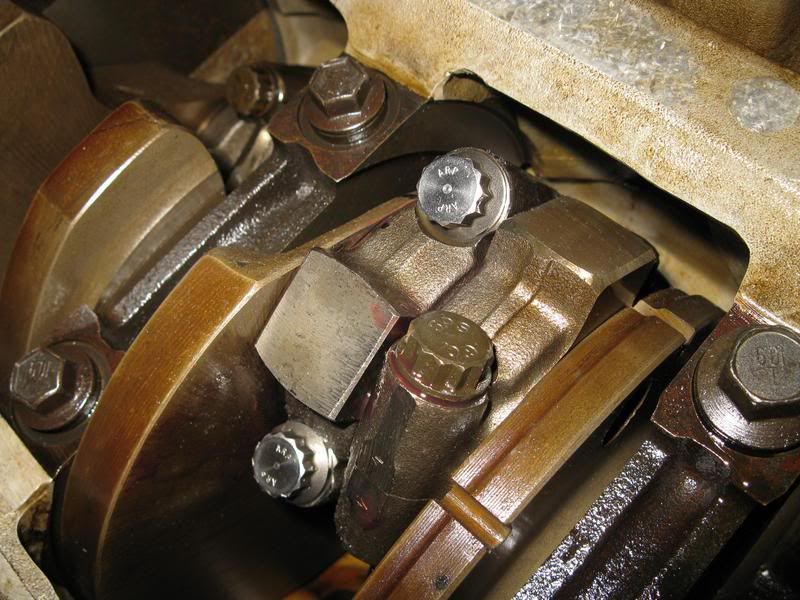

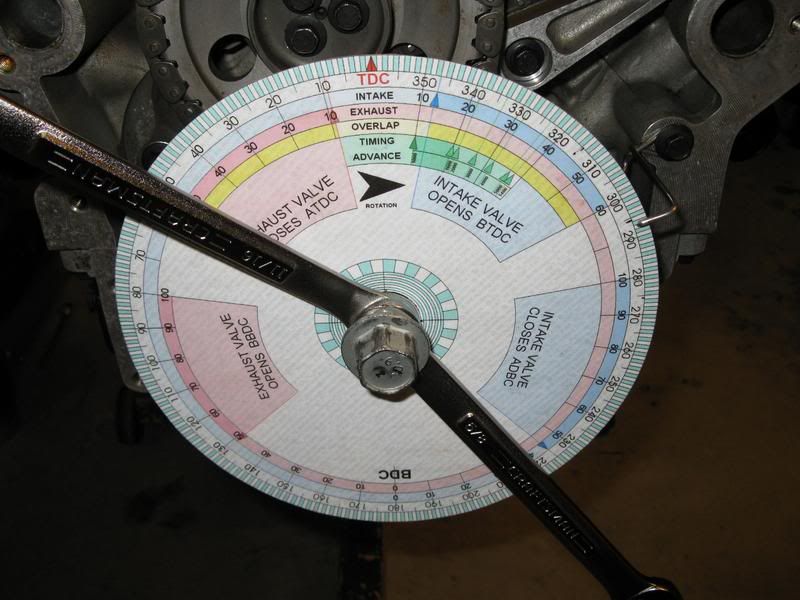

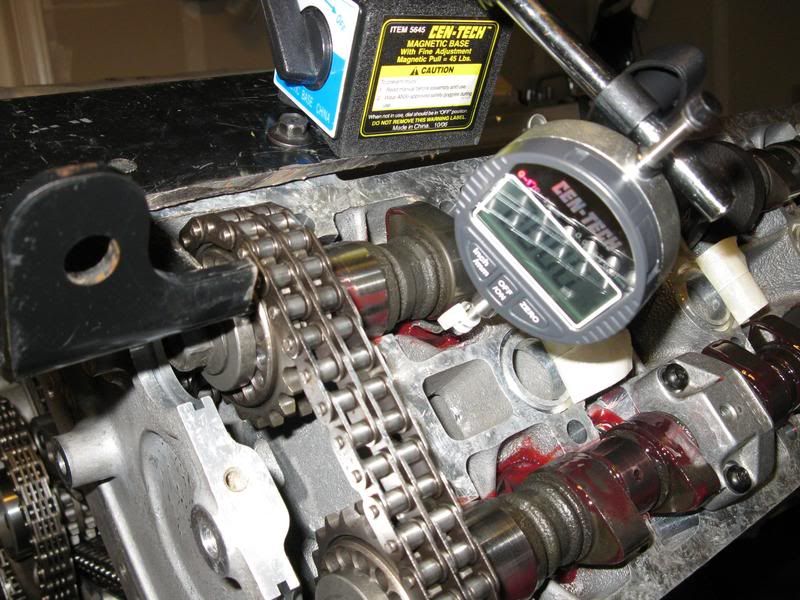

Time to get this beast timed! I used Marc Haibeck's LT5 timing article and also Dynomite's write up on timing his LT5 (links to both below for reference). http://www.zr1specialist.com/HAT%20W..._camshafts.htm http://www.zr1.net/forum/showthread....7524&post87524 Before moving on to the timing process, I installed the 2 new ARP rod bolts I ordered from Haibeck for that one piston I had to remove. I weighed both the ARP bolts and the original bolts and they are all the same (1.3oz IIRC), so the balance of the rotating mass won't be compromised. I used the GM torquing procedure since I don't have one of those fancy bolt stretch gauges. Marc lists the GM procedure as an "alternate" procedure for torquing the ARP rod bolts.  Now on to the timing. First I mounted my timing wheel to the front of the crank snout. I made a pointer out of a metal hanger and bolted it to one of the front cover holes.  I installed the positive piston stop tool that I made in cylinder #1 so I could locate TDC (Top Dead Center). To get the timing wheel lined up with the exact TDC, turn the engine crank one direction till it stops and make a mark on the timing wheel where the pointer is at. Then turn the crank the other way until it stops and make another mark at the pointer. Then count the degrees in between and find the exact center. This is where the exact TDC of cylinder #1 is. An alternate method of locating TDC without the piston stop tool would be to get the center of the deep notch on the crank lined up with the exact center of the crank sensor (or use the deep notch locating tool if you have it and your oil pan is still on). The crank is now located at 51 degrees BTDC (Before TDC). You can then set your timing wheel at the pointer to 51 degrees BTDC. Now when you turn the crank to the TDC mark (0 degrees) on the timing wheel, you will be at TDC on cylinder #1. The best way to start is to first follow the factory method of timing the LT5. This way you know the cams are in the correct positions in relation to the crankshaft and are not going to cause valves to hit the pistons. From there you can fine tune the cam positions. Now, I did not have the tight-fitting hold down caps. So far I've been getting by without having any of the LT5 Kent Moore tools, but those hold down caps are something that you really can't get away with not having if you want to get your cams timed accurately. I made do with putting some special tape on the stock cam retainers to make up for the gap (the details are in the previous update). While I did manage to make this work, I found I had to keep replacing the tape because after more than a couple back-and-forth rotations of the crank, the 3 tape layers would start to crumple and come off. And I even put grease between the tape and the cams. If I have to ever do this again, I will be getting the proper hold-down clamps, they will make the timing process much easier. The next thing to do was to get my dial indicator mounted. I started with the driver's side intake cam. I happened to have a piece of 1/4" steel plate with a couple of holes and a small bent over section also with a hole in it. This was an ideal way to provide a magnetic mounting surface for my dial indicator holder. I also made an offset tip for the dial indicator with a section of a large cotter pin bent into shape, the part that would be contacting the lifter rounded off with a file and mounted to the dial indicator with zipties.  Since my LT5 is completely stock, I timed my cams according to Haibeck's recommendation which is 114 Deg ATDC for the intake cams and 110 Deg BTDC for the exhaust cams. He says this will give you a nice broad range of power and torque (3-7K RPM) which is a really good setting for drivability. This also happens to be the stock timing settings for the 405HP LT5's. The 375HP LT5's were timed to 114 Deg for both the intake and exhaust cams. I guess Lotus figured out that changing the exhaust cams to 110 BTDC setting gave better power. Although like Marc reports in his article, due to the lack of accuracy of the factory timing method, the timing of each cam can be off by as much as 4 degrees or so either way. So it is worth it to properly set the timing even on a stock LT5. With the dial indicator mounted to the driver's side intake cam (primary lobe, the one with a 'pointier' tip), I turned the crankshaft to put the cam in a position where cylinder #1 was not depressing the intake valves. I then zeroed the dial indicator. I used the original cam bolts during timing setting process so I wouldn't mess up the ARP cam bolts. Since they wouldn't be tightened fully, they would work fine for just snugging the bolt to check the timing. With the cam bolt snugged down, now I could check the timing of the driver's intake cam. Normal engine rotation is clockwise when facing the front cover of the engine and this is the direction you want to turn the crank when checking the timing. I used Marc's suggestion of .010" either side of max lift. So first I turned the crank clockwise until I found the max lift indicated on the dial indicator. Then I turned the crank until I reached .010" before max lift, recorded the degrees at the pointer on the timing wheel, turned the crank until .010" after max lift and recorded the degrees at the pointer again. So if the max lift was .389", you would go to .379" on either side of that max lift and record the degrees from the timing wheel on the crank. With the degree readings recorded, I just added them together and divided the result by 2. So if you got readings of 131 Deg and 95 Deg you would add those together to get 226. Divide that number by 2 and you get 113 Deg. This is the degrees that the center-line of the lobe on the cam you are checking is timed to in relation to the crankshaft. I found it is helpful to make marks with a fine-tipped Sharpie on the back of the cam sprocket where the cam meets it like in the picture below. That way when you have to readjust the cam, you can see where you started from and what degrees the cam was set to at that point. You can then start to get a feel for how much you have to turn the cam to get the setting you are aiming for. Which, it turns out is a very, very small amount once you are within several degrees of the setting you are aiming for. So I just continued re-adjusting and re-checking the cam until I got it to where I wanted it.  Once I got the driver's side intake cam set to the 114 Deg ATDC (actually I set the intake cams to 113 Deg ATDC & 111 Deg BTDC for the exhaust cams to account for continued timing chain wear as suggested by Marc in his timing article), I removed the old cam bolt, coated the washer with clean engine oil, put loctite 262 on the new ARP cam bolt and torqued it according to the factory procedure. For the final torquing, I found a way to hold the other end of the cam so that it would not move at all during the tightening procedure. This method also allows you to final tighten the cam bolts without having to have another person to help you. The pictures below show what I did. For the passenger side, I had to turn the engine sideways to use this method because the tightening direction is the opposite way on that side.

__________________

[IMG]http://i13.photobucket.com/albums/a292/bdw18_123/_zr1netforumsigphoto.jpg[/IMG][B] 1990 Corvette ZR-1 [/B][I] White/Flame Red, #2299, mostly stock, 144K miles.[/I] -Cams timed to the '93-'95 405HP LT5 stock timing. -IAT sensor relocated to below front bumper. -Haibeck hoops installed in airduct. -OBX cat-back exhaust. [COLOR=DarkRed][B](SOLD - December 2012 [/B][/COLOR][COLOR=DarkRed][B]:hello:)[/B][/COLOR] 1993 Corvette Coupe Black/Black, 6-speed (SOLD - October 2009 :hello:) Last edited by bdw18_123; 04-20-2011 at 04:18 PM. |

|

|

|

|

|