|

|

#31 |

|

Join Date: Aug 2014

Location: Trois-Rivieres (QC)

Posts: 473

|

No unusual oil consumption, oil pressure is also good.

New code showed up today. Code #55: System Voltage. When I first went to buy the car, the previous owner told me to come back because the alternator was broken, so he can put a brand new alternator. Since I got this car, at night, I can see the dash lighting isn't stable at all. But, like I just told you, the alternator is brand new. And at idle it does seem it "wants" to die (idle at about 600 RPM, which is a bit low). |

|

|

|

|

|

#32 |

|

Join Date: Aug 2014

Location: Trois-Rivieres (QC)

Posts: 473

|

Wait, is there a mistake? At some places it says that code #55 is System voltage and some other places it says Fuel lean monitor...

I'm not sure if I already mentionned it, but previous owner told me the injectors were brand new (and I know he's honest). |

|

|

|

|

|

#33 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

battery terminals tight?

Alternators can fail even when new....whats the voltage its producing?

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

#34 |

Join Date: Aug 2006

Location: McLean, VA

Posts: 3,725

|

I believe DTC 55 is "fuel monitor lean". I would start with fuel pressure - fuel pumps followed by injectors. Not too many sellers are eager to replace injectors because typical dealer charge to replace 16 injectors is $3,500 to 4,000. Not saying previous owner did not replace them. Just don't assume they were replaced.

|

|

|

|

|

|

#35 | ||

|

Join Date: Aug 2014

Location: Trois-Rivieres (QC)

Posts: 473

|

Quote:

Just hooked a multimeter to the battery terminals: OFF: 12.4V Idle: 14.3V (constant between 14.32V and 14.36V) Quote:

I already tested the fuel pressure yesterday: Idle: 41 psi FP1: 46 psi FP2: 48 psi I'm officially not running this car anymore now, until it gets fixed. |

||

|

|

|

|

|

#36 |

Join Date: Jan 2015

Location: Marietta, GA USA

Posts: 1,160

|

Are there any other ZR-1's near you? If yes, maybe you could borrow their ECU briefly to see if it makes a difference. My ECU has been in two other cars and that helped them narrow down the possible cause for their rough-running conditions.

Kind of shocking a dealer would charge $3,500-$4,000 to change injectors, but, then again, maybe not that shocking. |

|

|

|

|

|

#37 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

fuel pumps replaced? possible the clips/clamps for the lines are loose and bleeding pressure?

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

#38 |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,493

|

Well, I gotta give you credit...you are tenacious! However, some things are obvious that are giving you a lot of frustration too. And, too I think most would agree that you have touched on the problem, or been close, but just didn't realize it. AND, too, you've gotten off on some tangents which is "muddying the waters" a bit... But! I can tell that once you become fully acquainted, you'll soon be answering questions for others! Don't get discouraged.

Hang in there! Hang in there!  First off, it appears you have at least 2 (if not more) issues going on: ONE being a CLOSED LOOP issue (as Jerry pointed out) TWO, a wiring issue - probable grounding (more common) The 4 RULES OF TROUBLESHOOTING

Knowing how the system works: These motors are NOT complicated, BUT the control/monitoring systems are specific and unique (e.g., open vs. closed loop operation) to the point that troubleshooting effectively w/o getting distracted really (almost) mandates one read the FSM from cover to cover. Doing so will provide an overview of the nuances, but also provides prepared troubleshooting guides and how to test stuff, etc. So, my first question is: Do you have an FSM?? Assume nothing...NOTHING! AND, measure! In that regard, you've touched on some pretty good indicators that at least narrows the problem(s) down considerably. And, too, it appears (to me) there my well be at least two different issues: closed loop issue, and an electrical malady. One issue at a time: The "BUCKING" issue is the highest priority (now). (Note: Sometimes two or more issues have commonality - especially electrical, but it is best to stay focused and work the issues individually. (Otherwise, it can easily get confusing and contradictory...did I mention frustrating?) Hear is a summary of what you've tested or experienced (or attempted to test)*:

Divide and eliminate! This problem is really in two (?) parts. With knowing how the system works, symptoms and measurement data too can be grouped separately and then prioritized. In this case, those items that are related to the rough running, primarily in "closed loop" and NOT at WOT points to closed loop components; i.e., injectors, fuel pressure, MAP sensor, O2 sensors, Throttle Position Switch (aka TPS), and ECM. As mentioned, checking for codes is always a good way to gather a lot of information. HOWEVER, often old codes that are no longer applicable linger in the memory. Disconnecting the power to the ECM for a minute or so will clear the memory. Sometimes codes are stored that no longer apply which can send us in the wrong directions. But, also some problems are not instantly recorded/stored: erasing them could remove important clues. So, to play it safe, it is a good thing to note what problems are stored before clearing the ECM to "clean the slate". Clearing is a good tool, but it is tricky. (And, sometimes a code is set that does not appear to be directly associated with the actual fault. This happens especially if the fault effects more than one sensor, e.g., injectors.)[I] Rough idle and or a knocking sound (dual mass FW**), low rpm, stalling, running OK when cold, but rough when it warms up, running OK with rpm and/or moderate to heavy throttle (esp. WOT) are classic fuel delivery issues at CLOSED LOOP ONLY.

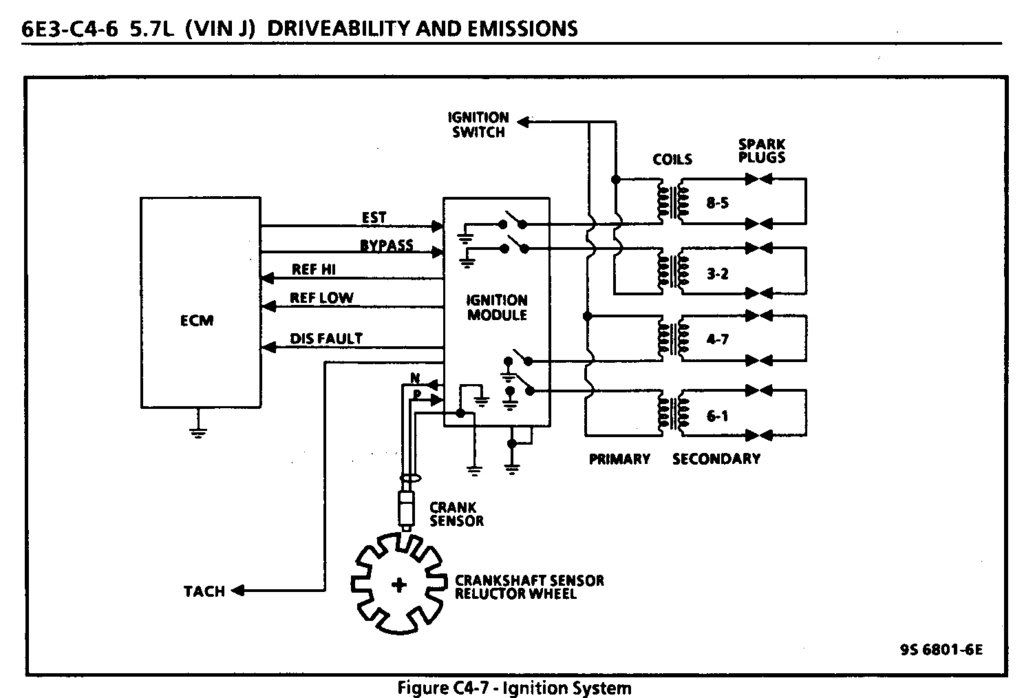

Running strong at (OPEN LOOP) tends to eliminate fuel delivery pretty much in your case. However, just for the record (FYI) a dynamic fuel test will expose weak pumps or plugged in-line filter (you DO know there is an in-line filter (located just behind the front passenger wheel housing), yes?  In closed loop conditions, and fully warmed up, the dynamic pressure will be around 42-45 psi. in open loop conditions the combined fuel pressure will be 52-55 psi. Injectors: My injectors had just been replaced when I bought my 90 Z. At issue was they were replaced with NOS, and they too went bad due to alcohol exposure! SO! Unless you've checked resistance when the motor is fully warmed up, you can't be sure they are good. Typically the shellac-insulaiton on coils fails, it goes undetected until the coil is heated. There are a couple ways to take the resistance readings. How and under what teperature conditions did you test yours, may I ask? Throttle Position Switch: Sometimes the TPS wiper is dirty or has failed. This too is FYI, and not related to closed loop per se'. By disconnecting the electrical plug you can operate the TPS through its enter throttle range while watching the (analog) resistance indicator on the VOM, looking for a smooth change in resistance through the entire range. With the connector reassembled and the ignition switch to ON, motor OFF, the TB wiper should be set to 5.5 VDC. O2 sensors: The O2 sensor operation (including 'cross counts') can easily be monitored with a dynamic scan (most auto parts stores have that capability). And, also, the sensor can be removed and tested with a VOM and a propane torch. https://axleaddict.com/auto-repair/H...-Oxygen-Sensor A lazy (low # of cross-counts) or non-responding O2 sensor, especially an intermittently failing one can result in a number of closed loop symptoms (but not exclusive of closed loop operation either!) - especially idle irregularities and rough running, fouled plugs (on one bake only...is important to note) are some of the more common issues. Not because of your symptoms in particular, but more of an FYI, you asked about checking the coils. Well, the acid test for ignition is proper operation at WOT when the motor is fully warmed up! Furthermore, a pin-hole can develop in a wiring insulation that cannot be detected with a standard VOM: a MEGGAR or dedicated test equipment is required, which is uncommon except in the better repair shops. The LT5 uses a "waste spark" design. Each coil fires two plugs at the same time.  That said, the resistance can be measured across the spark terminals and compared with the readings across all 4 coils. (But, again, not all coils e.g., AC/Delco, MDS, Excel, etc. read the same, specifically, and may vary from type to type!) Plug wires resistance values vary too, depending on the make/type. However, the resistance should be proportional to their length; i.e., a wire twice as long as another should have close to twice as much resistance as the shorter one. Well... w/o more specific info, this could get very superfluous (if not already!). So, I'll stop till I hear more specifics from you first.

__________________

Good carz, good food, good friendz = the best of timez! 90 #1202 "FBI" top end ported & relieved Cam timing by "Pete the Greek" Sans secondaries Chip & dyno tuning by Haibeck Automotive SW headers, X-pipe, MF muffs Former Secretary, ZR-1 Net Registry Last edited by Paul Workman; 05-15-2016 at 04:20 PM. |

|

|

|

|

|

#39 |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

fuel filter backwards?

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

#40 | |||

|

Join Date: Aug 2014

Location: Trois-Rivieres (QC)

Posts: 473

|

Quote:

Quote:

Quote:

I got the FSM, but I don't think I'm ready to read it from cover to cover. Maybe that would help me troubleshoot the problem though. Useful summary with some corrections: 1. "Bucking" at <3000 rpm AND especially after it warms up (but not before) 2. The tach reading is erratic at times 3. NO SES light Yes, code 55 and code 64. They appeared some miles after I installed the new fuel filter (as well as the knocking noise). I think this is a pure coincidence though. 4. Injectors "tested" *** Last fall, electrically tested 5. Haibeck chip installed 6. O2 wiring added on passenger side 7. O2s NOT checked 8. MAP connections "OK" 9. ECM connector repaired (!) 10. New fuel filter 11. knocking sound at idle, and low idle speed (600 rpm) And my primary concern now! Scary stuff! 12. Belt tensioner checked And loose 13. Dash lights flicker some The codes 55 and 64 aren't old codes. I plugged my ALDL Code Reader 4 days ago (even if I had no SES light) and no code was stored. SES light came on 2 days ago, code 64 showed up. Then, yesterday, after a 60 miles WOT pull, code 55 also showed up. I've ran with blown o2 sensors in a lot of cars. You really think this could be a problem on a ZR-1? I installed a WIX fuel filter. On it, there was a tiny black arrow --->. Fuel pumps ---> Fuel rail. Rear ---> Front. That's how I installed it. |

|||

|

|

|

|

|

|