|

|

|

|

#1 |

|

Join Date: Feb 2006

Posts: 2

|

I,m looking for more info on reinstalling my cams and timing them ,also the install on the chain tensioners ,need to put my heads back on and set everything back up , I have the assembly manual but like to know if there are any other little trick that make it easier or better

|

|

|

|

|

|

#2 |

Join Date: Jan 2004

Location: Alex VA

Posts: 1,087

|

take a look at www.zr1specialist.com

I believe he has a good procedure on the cam timing. you do need a few special tools to make it easier. takes a bit of patience and is easier to do with the engine out of the car. good luck!!

__________________

95 390 LPE ZR1 (505 rwhp) LSV = Lingenfelter Super Vette Twin Turbo 2003 Z06 (800 RWHP) |

|

|

|

|

|

#3 |

Join Date: Sep 2005

Location: Dallas, Texas

Posts: 14

|

I did a thing on cam timing a few years ago. Depending on year, it can move dramatically. Early models (375 hp) with one flat on the venier can swing easily 6 degrees either way. Later models with two flats are tighter but still can move. Doing the timing according to factory procedures does not yield consistant results at all.

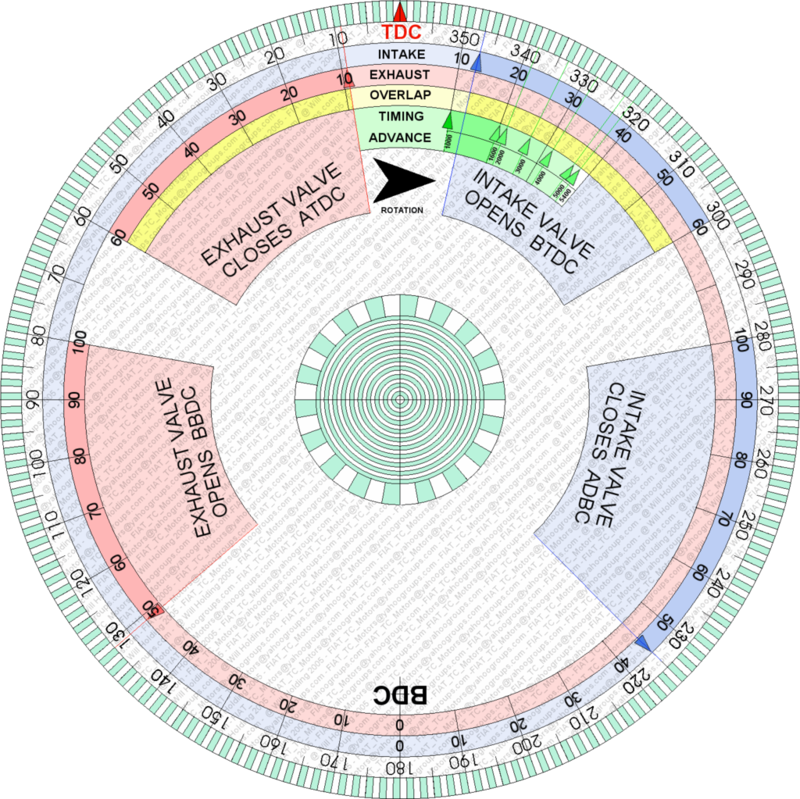

To get good timing you will need a piston stop to get TDC accurate. You need to get a standard timing wheel to do this. If you have a good CAD program you can make one out of paper, back it with cardboard, and tape it to the dampener. I have done this several times when timing the cams in the car. You will need a dial indicator to place on the lifter with a fixture you make to go around the cam shaft and sit atop the lifter. You will need a crank locator pin as well as two temporary cam chain tensioners. You will also need temporary cam retainers to secure the cams to the head. You will need a torque angle meter for the cam bolts. Finally you will need four cam locator pins. As far as parts you will need four new cam bolts. This is at a minimum. You may need new tensioners if you cannot reset the old ones. I did a photo set on the Corvette Forum explaining how to do this. If you don't know how to do it then you will probably screw one up before understanding how it works. Quickly, when resetting the tensioners you are resetting the travel snap rings in order that the tensioners can be installed cocked. Once installed, a quick tap in the tensioners will fire them allowing for full travel. First, you will need to time the cams according to factory procedures. This is done mainly to assure that there is no interference with the pistons and valves. Next, find TDC on the #1 cylinder. Do this using the piston stop. Now you can set up the dial indicator on the #1 cylinder. Measure the timing on the cam you are working on. This can vary widely as you will find out. You measure the timing on a cam by turning the crank clockwise. Determine the max lift in the lobe approximately. Turn the dial indicator pointer to that setting. Now, to make an accurate measurement, you turn the crank clockwise until you are about .020 on the dial indicator before your pointer. Say that is 124 degrees on your timing wheel. Next, keep turing the crank past your pointer on the dial indicator until you get back to the .020 you took the first measurement at. Read the timing wheel, say it's at 95 degrees. Now you add 124 and 95 to get 219 and divide that by 2 to get 109.5. That is where the cam is timed at. If you don't understand this procedure then you don't need to be timing cams. When timing cams you can be close and that is fine. Just make sure they are close to equal for intakes and close to equal for exhaust. On the intakes you can go anywhere from 108 to 114. 110 is ideal, 108 gets more power but less torque. I have gone down as far as 103 before. On the exhaust you can go between 114 and 116. The hardest part of cam timing is locking down the cam bolt. There can be no movement. I have found that when I have gotten the proper timing I take a small piece of cardboard and place it under each of the temporary retainers and torque them back down. Do this one at a time. Next, get someone to hold the rear of the cam in place with a wrench. Now you can begin the torquing. When you are doing the torque angle you have to keep a close eye on the dial indicator. It has to stay in one place. If you see it move you have just killed your timing and must repeat the procedure over. You will be turing the cam bolt 80-85 degrees all the while keeping a close eye on the dial indicator. Meanwhile, your assistant at the other end of the cam is applying opposite pressure trying to maintain the cam in the proper place. EASY! Needless to say, if you have never timed a cam you are pretty assured of not getting it right the first time. If you know someone close to you doing a timing then by all means go there and watch and help. |

|

|

|

|

|

#4 |

|

Join Date: Apr 2009

Location: Prather, CA

Posts: 809

|

I've got Haibeck's timing chain article printed out and in my LT5 service manual. While I can read it, the scan quality is very poor, would be nice to have a higher resolution version.

I've gotta do some serious studying on this procedure when I get ready to reassemble my '90 LT5. Also have to make the special tools that I can and buy the ones I can't. Will definitely be a learning experience, but I know I can do it. I'm planning on printing out this degree wheel that I found on the internet (can't remember where) and mounting it on cardboard or thin plastic. Will it work ok to use this on the LT5? (I reduced the size for posting, the one I have is much larger)

__________________

[IMG]http://i13.photobucket.com/albums/a292/bdw18_123/_zr1netforumsigphoto.jpg[/IMG][B] 1990 Corvette ZR-1 [/B][I] White/Flame Red, #2299, mostly stock, 144K miles.[/I] -Cams timed to the '93-'95 405HP LT5 stock timing. -IAT sensor relocated to below front bumper. -Haibeck hoops installed in airduct. -OBX cat-back exhaust. [COLOR=DarkRed][B](SOLD - December 2012 [/B][/COLOR][COLOR=DarkRed][B]:hello:)[/B][/COLOR] 1993 Corvette Coupe Black/Black, 6-speed (SOLD - October 2009 :hello:) Last edited by bdw18_123; 01-16-2010 at 06:42 PM. |

|

|

|

|

|

#5 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,708

|

Guys,

Forgive me if this is a really stupid question, but has anyone tried a tack weld on the cam sprocket/ cam interface? I know the 3rd Gen SHOs had an issue with cam timing and bent valves. Would it be possible to tack weld in such a way as to allow removal if you wanted to try another cam timing? |

|

|

|

|

|

#6 |

Join Date: Dec 2005

Location: Huntley IL

Posts: 170

|

yes we have, it works really well unless you move your camshafts once a week to find the most hp [like someone we know] then the front of the camshaft gets all beat up. And the info on where to put thoes cams at to make the most hp will cost you . it is locked up in a mayonaise jar in a garage in desplaines the only other option is top security clearence from the Pentagon, although a really Hot looking sheep might convince him to part with the info HA HA

Bob G |

|

|

|

|

|

#7 | |

Join Date: Jun 2006

Location: Sparks, NV

Posts: 2,852

|

Quote:

...... ...... H

__________________

90'ZR-1 #1461 Red/Black Ported Intake, Degreed Cams, OBX Headers & Exhaust, Fidanza FW, Secondary Delete, Custom tune, C6 GS Wheels. Sold 08 C6 Z51 Crystal Red Metallic Sold Vararam Intake, Tune, Sold 05 C6 Z51 Red/Black Sold 90'ZR-1 #1723 Black/Gray Sold but not forgotten 91' Z51 L98 White Vert. My First, you always remember your first. Sold. |

|

|

|

|

|

|

#8 | |

Join Date: Mar 2007

Location: Crystal Lake, IL

Posts: 7,194

|

Quote:

__________________

LGAFF 90 #966-150K miles-sold 92 #234-sold 1987 Callaway TT #17 1991 ZR-1 #1359 |

|

|

|

|

|

|

#9 | |

Join Date: Dec 2003

Location: Chicagoland,IL

Posts: 2,679

|

Quote:

Does she have a twin sister  Then i will tell where the mason jars are buried. Pete

__________________

'91 #1635 PoloGreen 350 LT5 11.09 @ 129.27 11.04 @ 128.86 474RWHP 400RWTQ http://www.youtube.com/watch?v=SFNFOhGGlR4 http://www.youtube.com/watch?v=ZlRIOMwaDYY https://sites.google.com/site/peteszr1garage |

|

|

|

|

|

|

#10 | |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,708

|

Quote:

I was thinking of Self Shielded Flux Core welding. When I worked at GMAD-Tarrytown(now lovely townhouses on the Hudson) this was the basic method to tack anything. Looks like it would be fairly easy to remove if you wanted to re-do cam timing. |

|

|

|

|

|

|

|