|

|

#1 |

|

Join Date: May 2013

Location: Chicago

Posts: 982

|

Anyone have a picture of the LT-5 motor mount on the engine? I am trying to diagnose and fix a lifting gear shift under load. I got under the car and can see the bolt and nut from the bottom that go into the mount but besides that nothing much else to see. I can feel around and seems like there are a couple of bolts on top of the mount.

The C-Beam bolts are all tight except for one up front that I could not get to while under the car. I also tried to lift the motor on each side with a piece of wood and it did not budge so it appears the mounts are good. Thanks! |

|

|

|

|

|

#2 | |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,685

|

Quote:

The C-beam bolts are the issue. Need to be torqued properly. Had same issue last year. Took it to Pete and we got it up on lift. |

|

|

|

|

|

|

#3 |

|

Join Date: May 2013

Location: Chicago

Posts: 982

|

Pete thinks a bolt may have backed out of one of the motor mounts. The C-Beam bolts are tight.

|

|

|

|

|

|

#4 |

Join Date: Oct 2004

Posts: 1,884

|

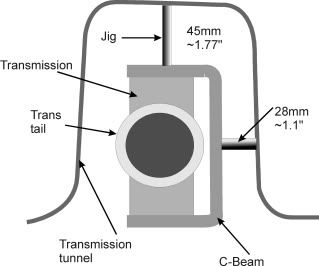

This is the orientation for all LT series engines in the C4 Corvette. #1 bracket to the engine and the mount to the engine retained by the thru bolt:

http://parts.nalleygmc.com/showAssem...=0&modelYear=0 |

|

|

|

|

|

#5 |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

Well...from what you describe, my money is still on the C-beam joint, probably the front (transmission joint) one. But, to find out for sure, I'd have to remove the C-beam and inspect the contact regions for scuffing, and/or distortion of the bolt holes, i.e., elongated holes, AND/OR a ridge around the edges of the steels washers is the dead giveaway the joint is slipping!

NOTE: Also, if the rear C-beam joint is slipping, the rear-end tends to kick out to the right under hard acceleration as mine also did. The cure for both for me was/is Boudreau's C-beam plates and some blue loctite to enhance friction between the mating surfaces (ref Bill Boudreau's ZFdoc.com site). While the C-beam is removed, the motor mounts can be tested by attempting to rotate the motor from side to side by applying pressure to one side and then the other with a (bottle) jack. Any movement can be explored to assure it is only the rubber flexing, and NOT a securing bolt(s) or broken parts at fault. Keep in touch!

|

|

|

|

|

|

#6 |

|

Join Date: May 2013

Location: Chicago

Posts: 982

|

I am going to get it taken care of. I have been working and driving my Prius.

Fun car, totally different vehicle though. I took the Z out for a spin today and I plan on dropping the exhaust so I can not only get a full view of the C-Beam but to also de-grease and clean up the area. Last time I pulled my hand out of that area it was greasy, slimy and dirty. |

|

|

|

|

|

#7 | |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

Quote:

Oh! And getting the C-beam centered correctly BEFORE torquing it down can make a difference, far as eliminating wear on the U-joints and/or eventual vibrations. (ref: Bill Boudreau, ZRdoc.com)

|

|

|

|

|

|

|

#8 |

|

Join Date: May 2013

Location: Chicago

Posts: 982

|

I fixed it yesterday. Took everything apart, cleaned and reassemble and no more lift.

if the weather holds I'm going back on the dyno |

|

|

|

|

|

|