With the liner and piston ring issues taken care of, I moved on to getting the heads installed.

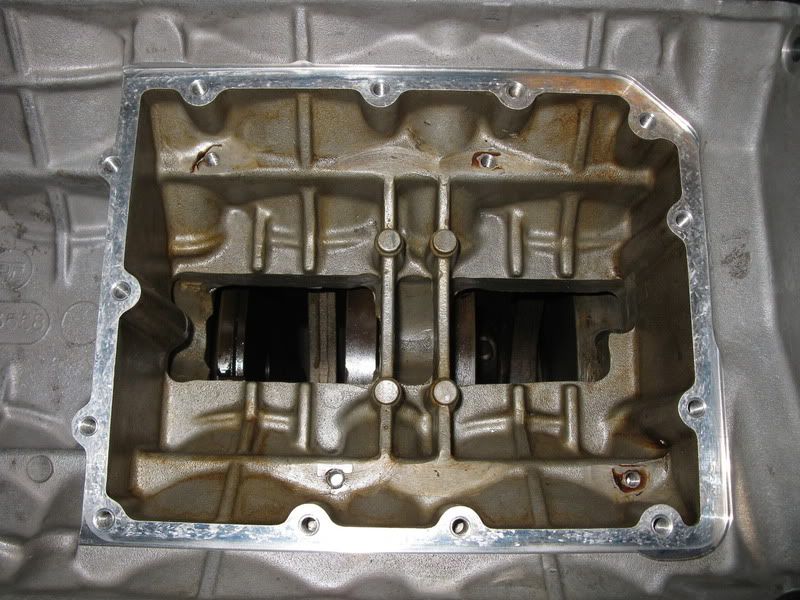

Before doing that though, I decided to remove the crankcase breather cover, remove the old gasket and get the gasket surface cleaned up. There was oil in a lot of the screw holes, which had to be cleaned out so that the loctite would be able to seal properly. I just turned the engine upside down and sprayed out the holes with carb cleaner (because I already had a can of it).

Now, on to the head installation.

First thing I did was get the head gasket surface area of the block cleaned up really good. I used a plastic scraper first to get the worse of the old gasket material off. Then I used some carb cleaner on a rag to scrub the surface. After that I used some scotch-brite to get the rest of the stubborn areas that didn't want to come off. I finished off with another wipe-down of the surface with the carb cleaner.

For the tops of the liners, I only used the carb cleaner and the plastic scraper. I used the scotch brite lightly on a few small areas between the liners where a tiny bit of corrosion had started.

The head gaskets I have are new OEM ones that I bought from Jerry awhile back. This was before he had his own head gaskets manufactured. I didn't know how long that would take and didn't want to be hung up on head gasket availability. Jerry at the time had 2 right hand GM head gaskets left and since you can use the right hand one on the left side, I bought his last two RH OEM ones which he gave to me for the RH & LH set price.

Here you can see the extra part of the RH gasket that has to be cut off when used on the LH side.

Gasket in place on LH side; the extra part is cut off.

With the gasket in place, I set the LH head in place. The dowel/sleeves are pretty tight fitting so it takes a bit of effort to get it lined up & in place, especially with how heavy the heads are.

I then just followed the procedure in the service manual. Put engine oil on the head bolt threads and washers, then torque them in three stages to the values specified and following the proper tightening sequence each time.

LH head installed and torqued down.