|

|

#11 | |

Join Date: Jun 2005

Location: pittsburgh

Posts: 4,633

|

Quote:

__________________

It's not the car, it's the people - Doug Johnson 90 r/r "KEYS ON" nick named "T.L.B" |

|

|

|

|

|

|

#12 |

|

Join Date: Aug 2014

Location: In my house

Posts: 103

|

All the main journal widths and diameters on the LT5 are smallish compared to the extreme high horse power motors I see running for more than a few mins, between rebuilds freshen ups.

These LT5 engines were built for endurance and longevity and they compromised peak HP for various factors, not to mention that the hood would have to be modified to allow for more direct airflow. Reversing and going for real high peak hp requires strength in the block and bottom end (plus rotating assembly) that the LT5 blocks never had. Sorta like 350 2bolt vrs 350 4 bolt vrs 350 4bolt truck vrs SB2 blocks vrs current Nascar blacks the more power required the more material and strength moves towards the bottom end, while the air/fuel passages are straightened/enlarged/optomized. If you look at the marine extreme high hp motors (made by any manufacturer) you will see where the materials are put when there is constant stress on the motors, they are good for about 50 hours running time, between freshenups.

__________________

Charter Member (since the 91) of the 1ST ZR1 Registry 1st vet $157.59. mo for 3 years new 2nd new 1 check & STILL eating funds years later [-X show poodles & trailer queens :-({|= Fast and fun not pretty in pink. |

|

|

|

|

|

#13 |

|

Join Date: Aug 2014

Location: In my house

Posts: 103

|

Put one of those engines on a dyno take it to your "800HP level", set the throttle, and let it run for just 5-10 Mins. Then come back let us know.

__________________

Charter Member (since the 91) of the 1ST ZR1 Registry 1st vet $157.59. mo for 3 years new 2nd new 1 check & STILL eating funds years later [-X show poodles & trailer queens :-({|= Fast and fun not pretty in pink. |

|

|

|

|

|

#14 |

Join Date: Jun 2005

Location: pittsburgh

Posts: 4,633

|

you pony up the money and I'll be happy to

__________________

It's not the car, it's the people - Doug Johnson 90 r/r "KEYS ON" nick named "T.L.B" |

|

|

|

|

|

#15 |

|

Join Date: Aug 2014

Location: In my house

Posts: 103

|

Post the dyno run sheets, showing that motor making 800HP you want me to pay to see. (So, I know you are not just pretending.)

Then you arrange its transport and we will hook it up to the Superflow. I have the wiring harness and flywheels from previous runs. We will video tape it, started and pegged at 95% power (that would be where it is making 760 hp) running for 10 mins for everyones' enjoyment. If it does not get to that 760HP, the motor comes right off and you pay the $2500 for the dyno hookup and runs... next...

__________________

Charter Member (since the 91) of the 1ST ZR1 Registry 1st vet $157.59. mo for 3 years new 2nd new 1 check & STILL eating funds years later [-X show poodles & trailer queens :-({|= Fast and fun not pretty in pink. Last edited by Harvie; 09-21-2014 at 04:38 PM. |

|

|

|

|

|

#16 | |

Join Date: Jun 2005

Location: pittsburgh

Posts: 4,633

|

Quote:

__________________

It's not the car, it's the people - Doug Johnson 90 r/r "KEYS ON" nick named "T.L.B" |

|

|

|

|

|

|

#17 |

|

Join Date: Aug 2008

Location: Houston 90 Red ZR-1

Posts: 2,320

|

Me being a CNC programmer/Machinist all my life and one who has done porting on the LT5 the problem is that you can only go so far down on a cnc before it turns into a 90 degree corner with the plenum. And unless they make a tool that can cut around corners the rest has to be done by hand. And at that point you have to use a ball gage. I made one for Pete and one for me. I know that some have used a telescoping gage. But you can't get a true 360 degree circumference with a gage that can only take a measurement 180 degrees at two tiny points.

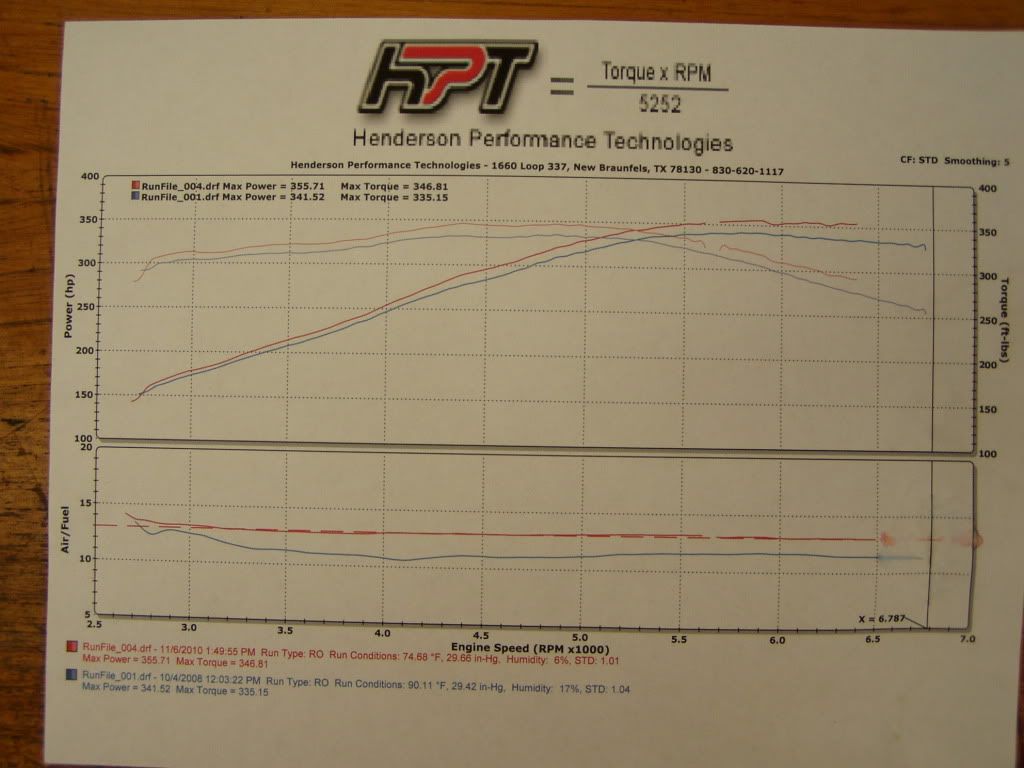

I charged $850 to do the IH and plenum/Siamese. And it took me 16 hours to do it right. It just wasn't profitable enough for me to keep doing. Mark H. Charges $1800 to do it. Corey charges $950. I would say $1500 is worth the trouble. And with porting alone your looking at maybe 15-20HP gain. With Jeal headers and A 3" B&B added along with a good tune your looking at 40hp gain realistically. 385-400rwhp This was with top end porting only. I was able to pull an extra 15rwhp and some more torque out of my 90 Z. And here's the proof at Corey Hendersons. The before and after overlay dynoes. No tune. No nothing and I was running lean on top of it.

Last edited by rhipsher; 09-21-2014 at 09:27 PM. |

|

|

|

|

|

#18 |

Join Date: Jul 2010

Location: Woodstock, Ontario, Canada

Posts: 1,275

|

Did I read here that Extrude hone will no longer do LT5 plenums due on their process causing damage?

__________________

peace Paul ZR-1 Net Registry Member #1494 |

|

|

|

|

|

#19 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,664

|

When I modified/ported my 84 Xfire manifold, EH is one thing I had done to it. Once I bought a ZR, I thought of doing the same thing. I contacted EH and was told they were no longer doing the LT-5 plenum because the pressure used in squeezing their abrasive through the plenum was cracking the runners from the main body of the plenum. True or not, don't know but that was the reason given. This was 7-8 years ago.

__________________

[SIGPIC][/SIGPIC]Former Membership Chairman Former ZR-1 Registry - BOD 1972 Corvette 4speed base Coupe SOLD long time ago 1984 Corvette Z-51/4+3 SOLD 1992 Corvette ZR-1 Aqua/Gray #474 SOLD 1992 Corvette ZR-1 Black Rose/Cognac #458 2014 Honda VFR Interceptor DX |

|

|

|

|

|

#20 | |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,493

|

Quote:

It was a 37.5mm gauge, as I recall. Some, like you too, have gone bigger - actually siamese'ing some or all of the runner length. And, apparently from what we saw in the LT5 2.0 AND at Mercury Racing last Friday, opening the runners to a single oval runner has merit. MM has eliminated the IH by placing the the injector directly in the head, just as the LT5 "2.0" (tho MM claims there is no DNA from the LT5 in their new line of 4-valve DOHC V8 racing motor...yeah, right!) One thing that has always been a bottle neck of LT5 mod information is the number of LT5s is so limited. Limited numbers brings relatively high cost and a smaller number of people that ported their motors. Consequently, specific porting experiment results has only been at a comparatively trickle pace, compared to say the "LSx" developments. Early on some deep pocket, big name shops like Lingenfelter and Calloway played a more active role and pushed the envelope agressively. But, that effort seemed to stop short of what is becoming more common now, far as development goes. (limiting discussion to stock bottom 5.7L motors). There are still some ponies to be dug out of the stock 5.7L top end for street driven cars. For example, Marc Haibeck upped his 500 crank hp package to 510 hp, due at least in part to some improvements to his previous porting architecture. And, then there's Pete with the help of cams and phasing is in the 560 hp range on a stock bottom LT5. So, there are still some ponies to be had. So, there is still a certain amount of had grinding/experimenting beyond what CNC maps are available. But, it seems the pickin is getting slim for a 5.7L block, normally aspirated. BOOST would appear to be a relatively open field for the 5.7L LT5, at this point. Porting: Always a very interesting topic...

__________________

Good carz, good food, good friendz = the best of timez! 90 #1202 "FBI" top end ported & relieved Cam timing by "Pete the Greek" Sans secondaries Chip & dyno tuning by Haibeck Automotive SW headers, X-pipe, MF muffs Former Secretary, ZR-1 Net Registry |

|

|

|

|

|

|

|